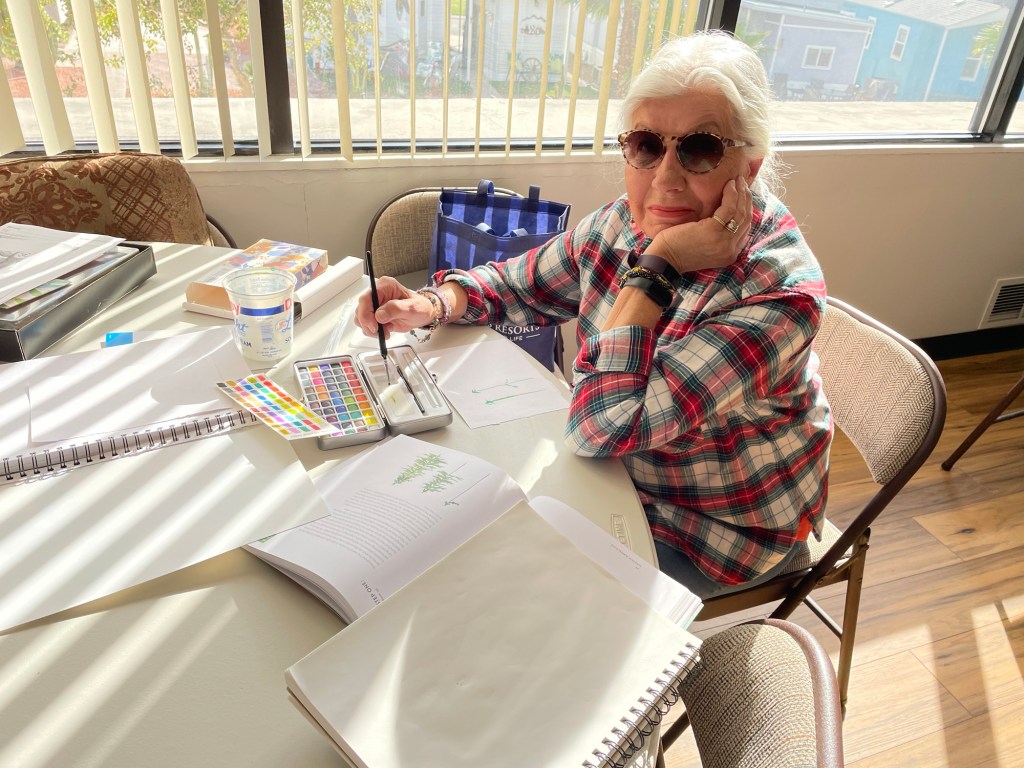

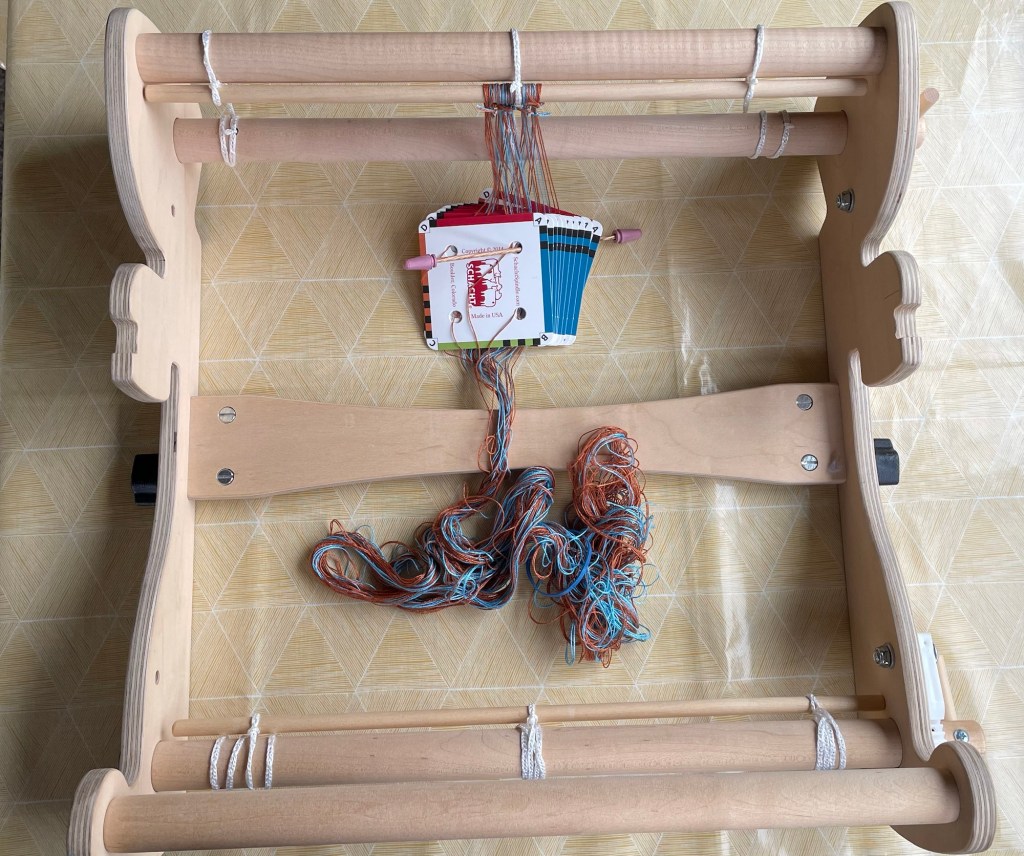

I friend of mine was helping clean out a storage room at her church. It was packed with crafting supplies that had not been used in a long time, including a table top weaving loom. She sent me a photo of the loom and asked if I wanted it. YES! I wanted this vintage four shaft Structo Artcraft loom.

I was not familiar with the brand, but found information online. Structo Artcraft looms have an interesting history starting in the early 1900’s. Structo Manufacturing, located in Freeport, Illinois, made metal toys. In 1921 they started making toy looms out of the same metal. Later they made looms for adults out of wood, eventually selling the Structo Artcraft Loom business to Dick Blick in 1972. The Dick Blick company manufactured and sold several sizes and models of the looms until 1981. You can find listings for Structo Artcraft looms on ebay, Etsy, and Craigs List. What you can’t find are current replacement parts. There is a Facebook group for people interested in these looms, so that is a place to look for information, advice or parts.

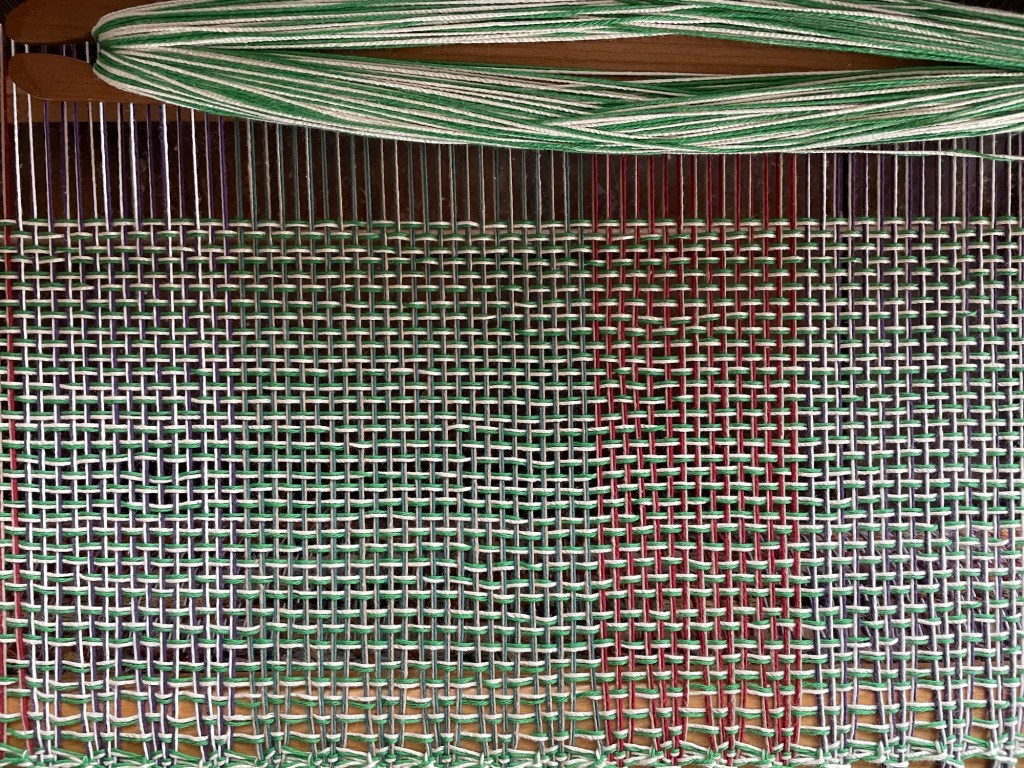

This loom is a hybrid of my other two looms. It has four harnesses, the same as my floor loom. The wood frame is 30″ wide with a weaving width of about 26″. My rigid heddle loom has a weaving width of 15″, while my floor loom has a weaving width of 36″. The 15 dent (ends per inch) reed on the Structo Artcraft loom is more dense than the reeds I have for my other looms. It seems to be in working condition, with a rag rug in progress.

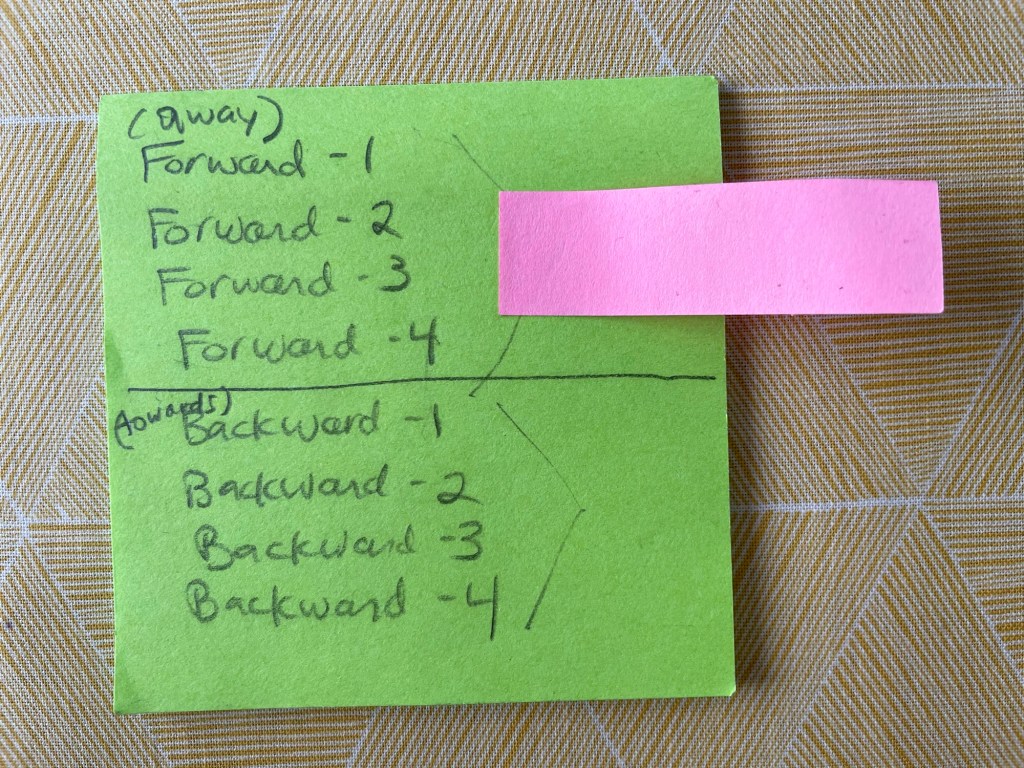

I am not interested in making a rag rug at this time, and I do not have the right materials to finish the one partway done on the loom. I had intended on cutting the rug off and re warping the loom with a different project. Then it occurred to me that I could just stop weaving the rug weft rows, and start weaving weft rows with some other yarn that I have, in order to try the loom and not waste the warp yarn.

One concern is that the handle to turn the front beam is missing, as shown in the photo above. On my floor loom there is one handle that is used for both the front and back beam. It is easy to move it back and forth as needed. On this Structo Artcraft loom the handle on the back beam is firmly attached, and I have seen photos of other Structo looms with two handles.

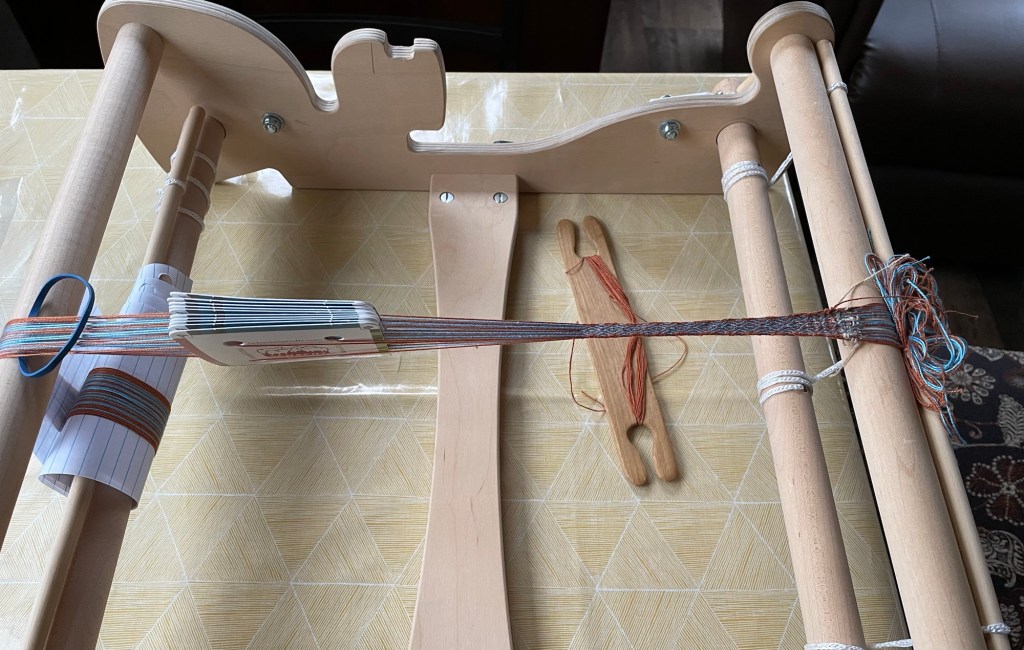

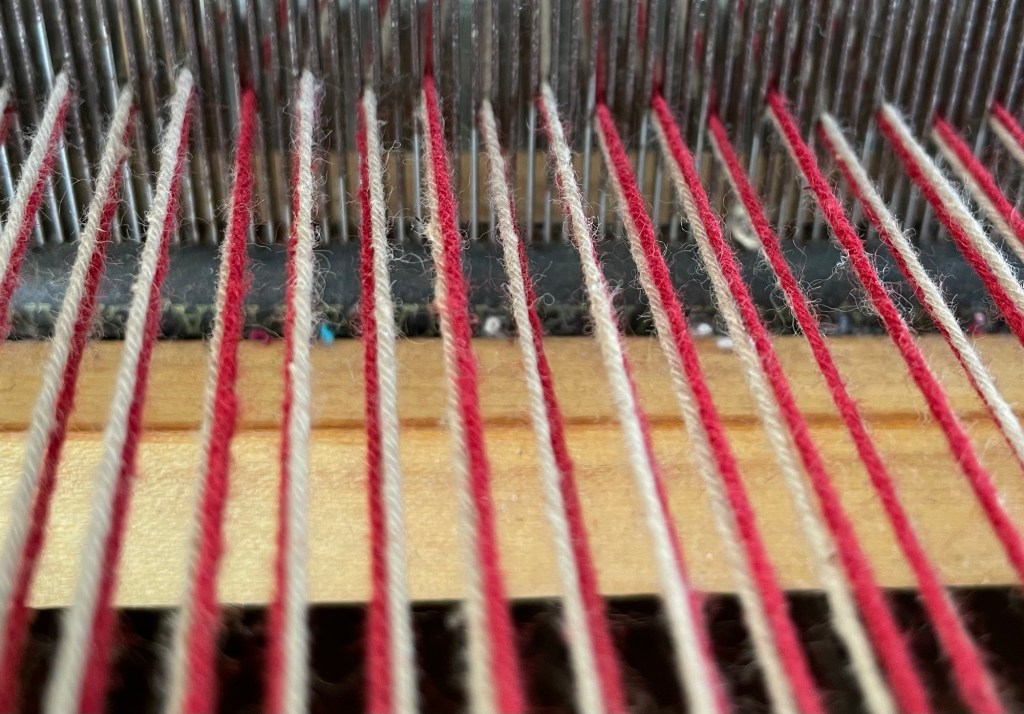

The yarn warped on the loom is something like 8/4 rug warp cotton, and not threaded through every slot in the reed. Instead there are two yarn ends together in a slot, followed by two empty slots. The weft “yarn” for the rug is a series of stretchy strips of fabric joined in a chain. The large space between warp yarns is needed for the thick rug weft “yarn”.

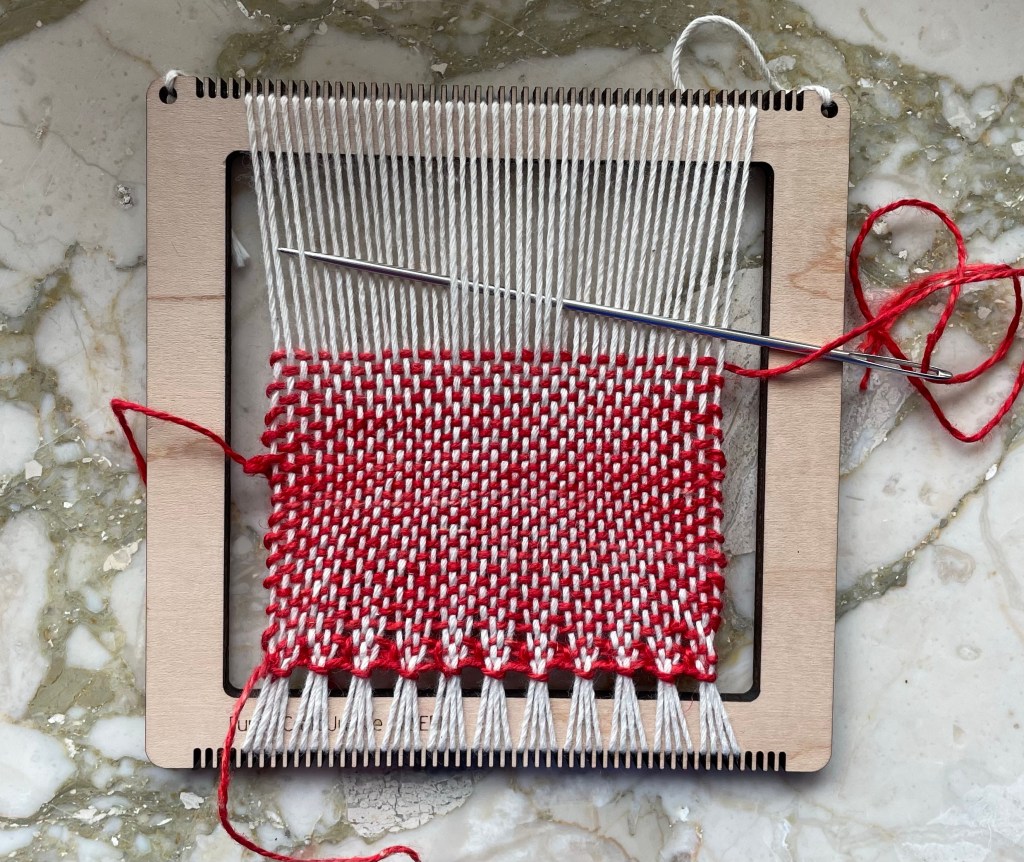

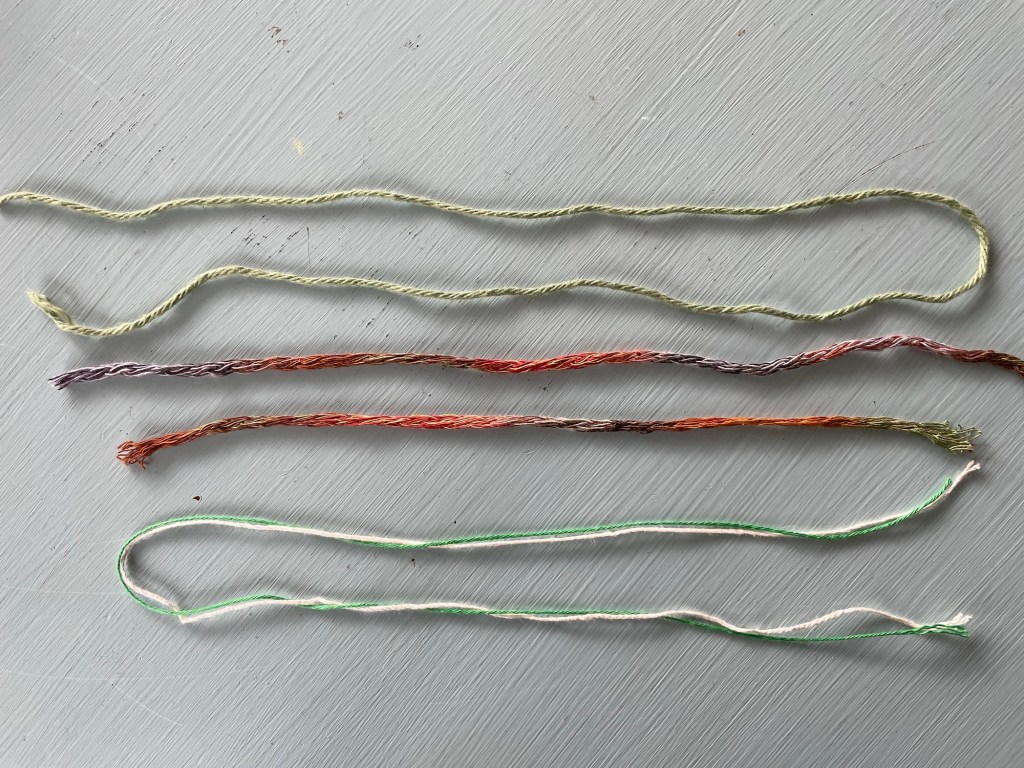

I found a couple of options for weft yarn in my stash. For my first attempt at weaving on this loom I chose some green Peaches & Creme 100% cotton yarn. It is not nearly as thick as the rug “yarn”, but it seemed like it would work. I wove a couple of rows, packing them close together, which resulted in a “weft faced” look where the weft yarn is dominant, like the rug.

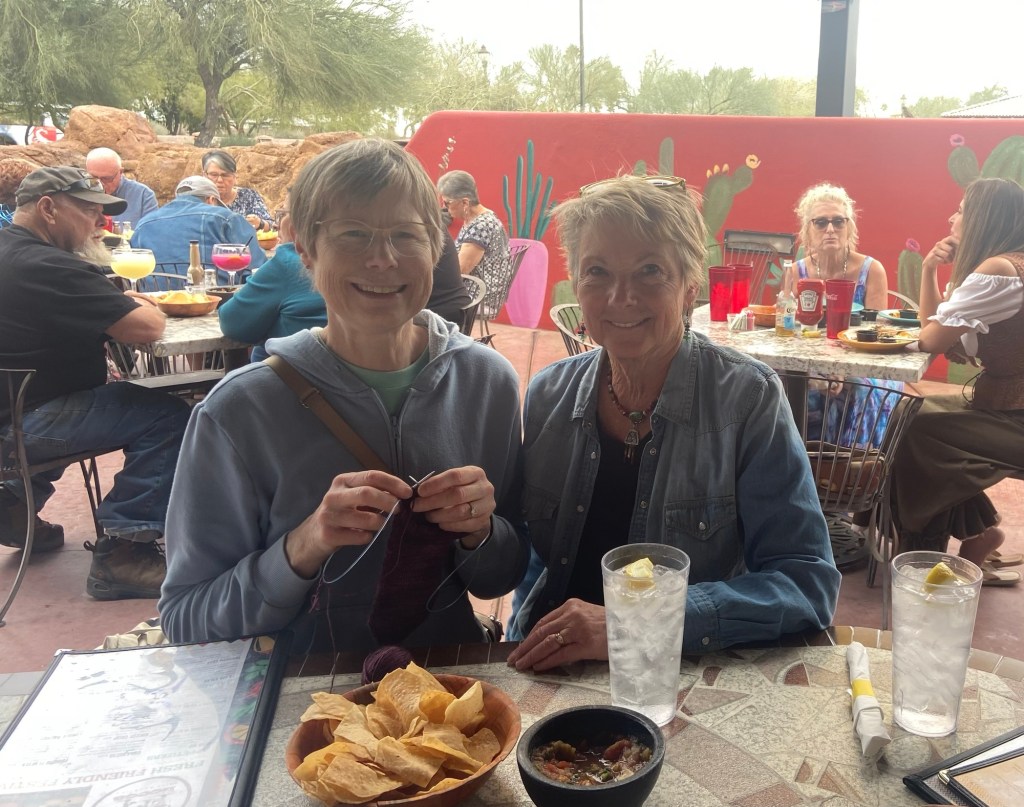

After talking to Torri, my weaving mentor, I started to place the weft rows farther apart in order to achieve a more “balanced” weave. This was all experimentation, a good opportunity to try some different things.

After using up the green cotton warp yarn on the shuttle, I was ready to try something else. I had some Berroco Espresso yarn that is thicker than the Peaches & Creme cotton. It is a 50% cotton / 50% polyester chain type (rather than plied) yarn. The colors went well with the various colors of warp yarn and the texture of the yarn made it more interesting.

I got around the problem of the missing handle by using a pair of pliers on the piece of metal sticking out where the handle would be attached, so I could turn the front beam. However my husband pointed out that would strip the grooves on the piece of metal that maybe were needed to hold the handle on, if there was one. After that I used my hands to roll the completed weaving onto the front beam.

After I ran out of the Berroco yarn I wove with two strands together of 8/4 cotton, one green and one white, which I believe is about the same thickness as the warp yarn. It is quite open, although it will shrink some when I wash it.

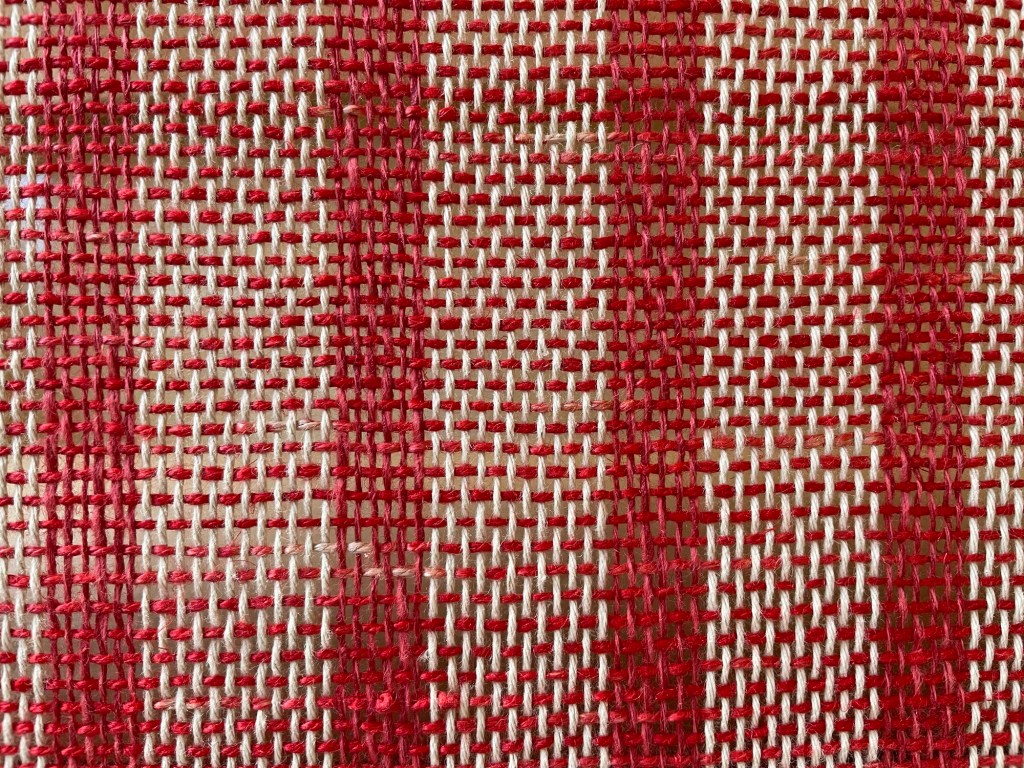

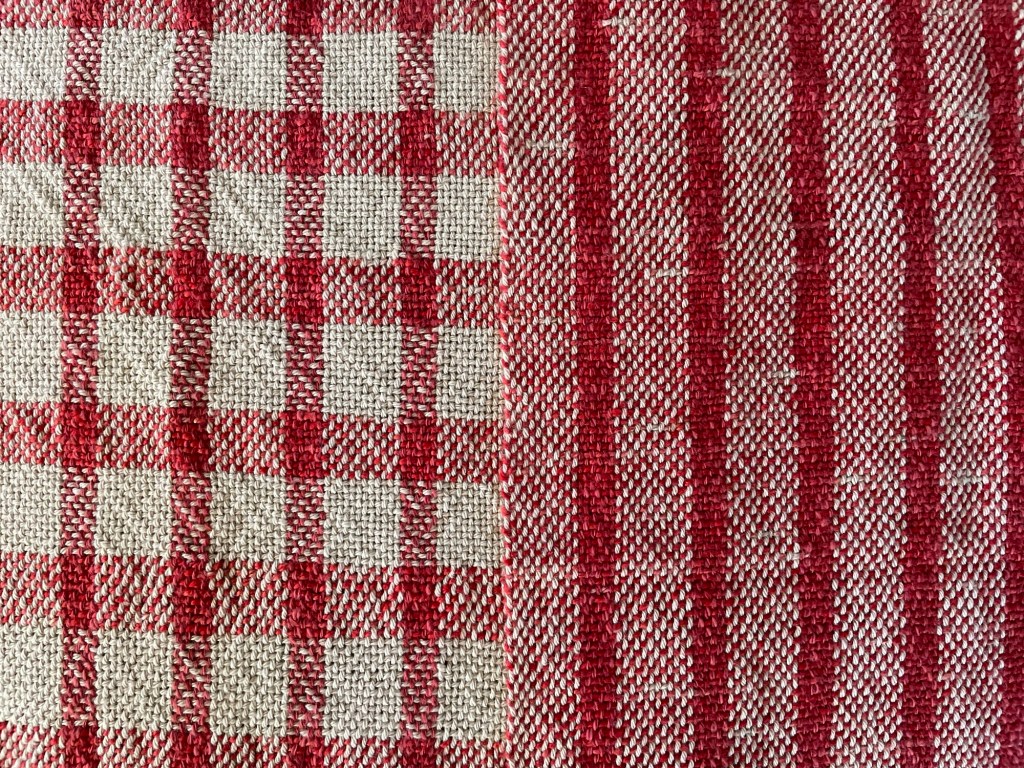

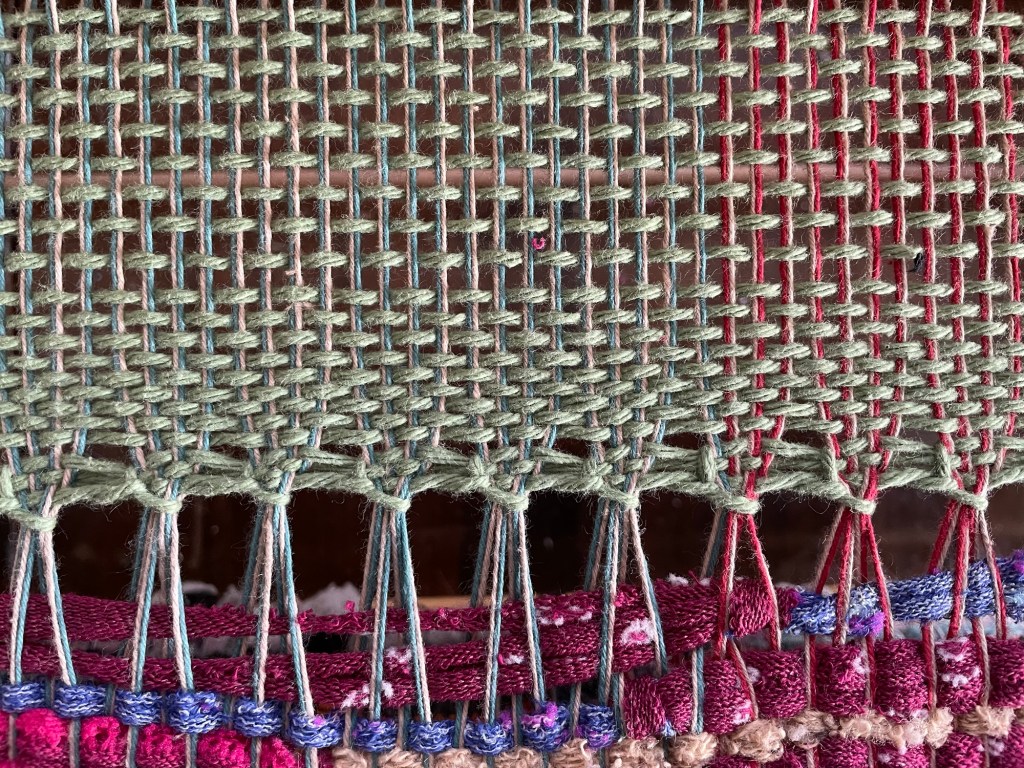

Following is a closeup photo of the three different weft yarns I tried (Peaches & Creme cotton, Berroco cotton/polyester, two strands of 8/4 cotton).

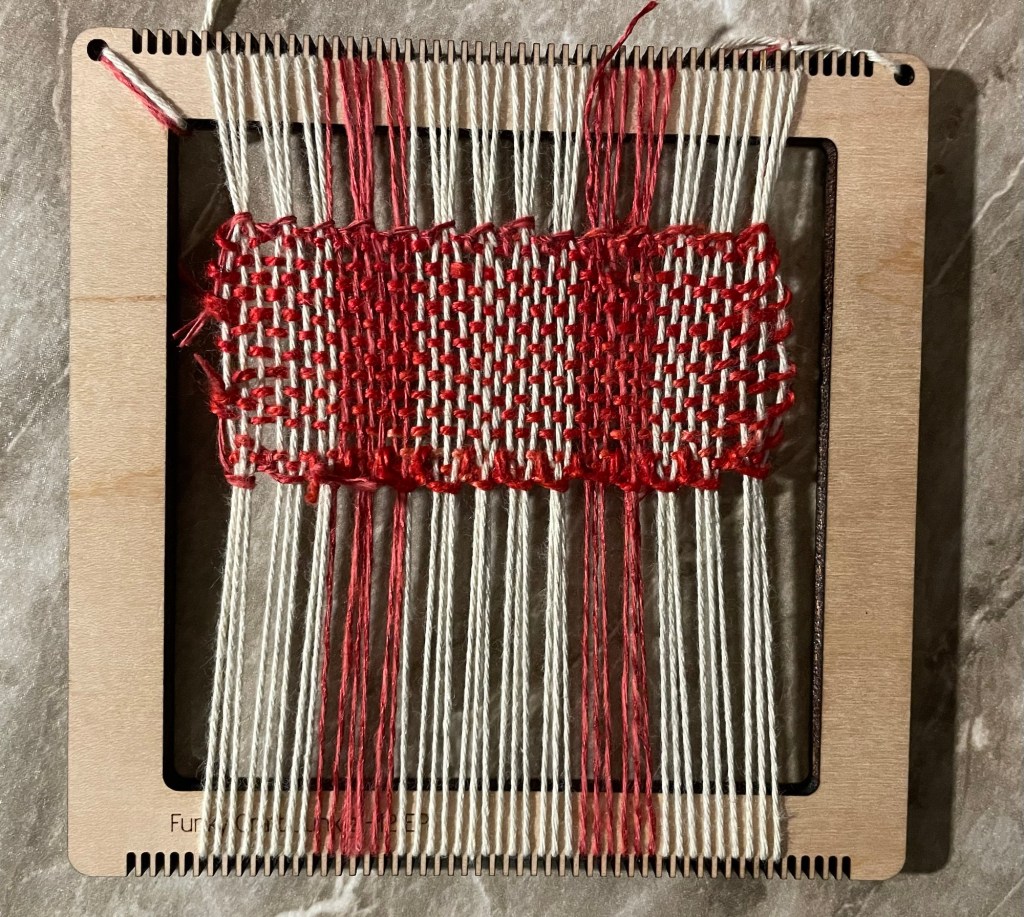

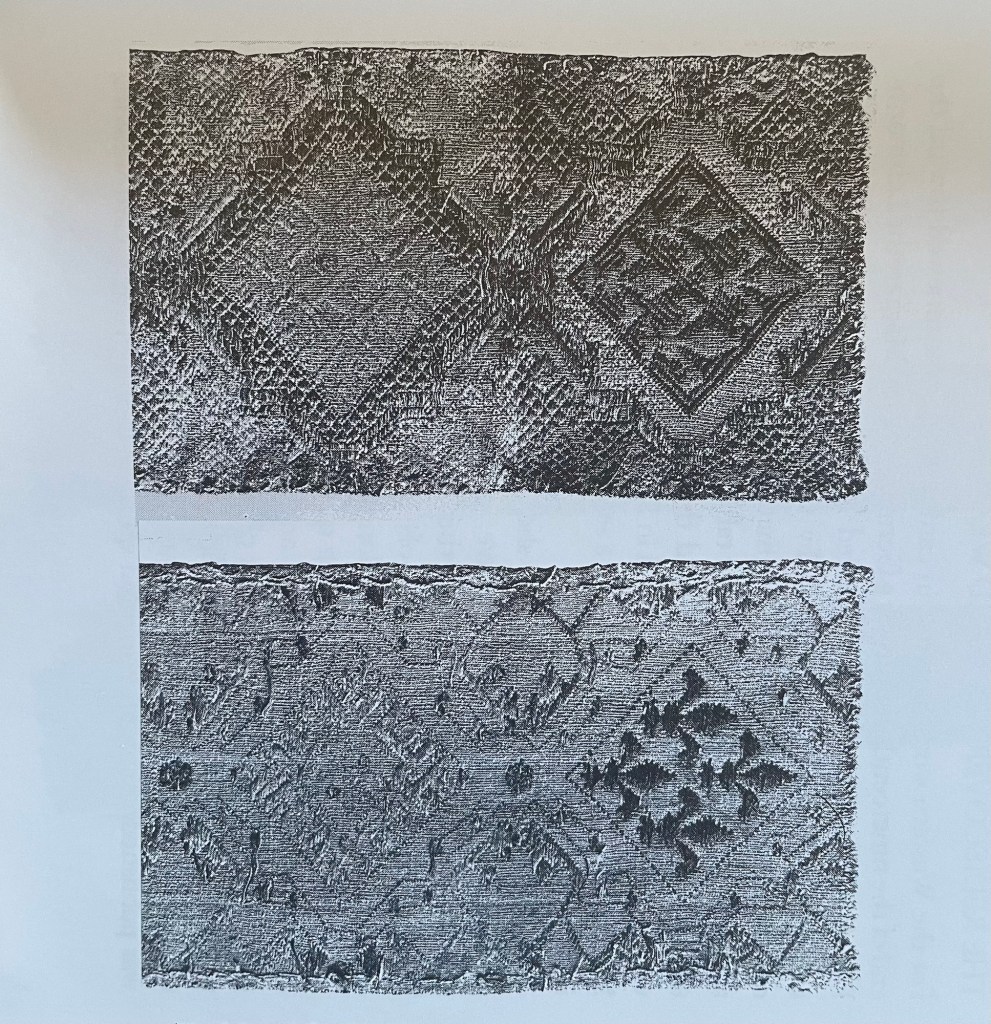

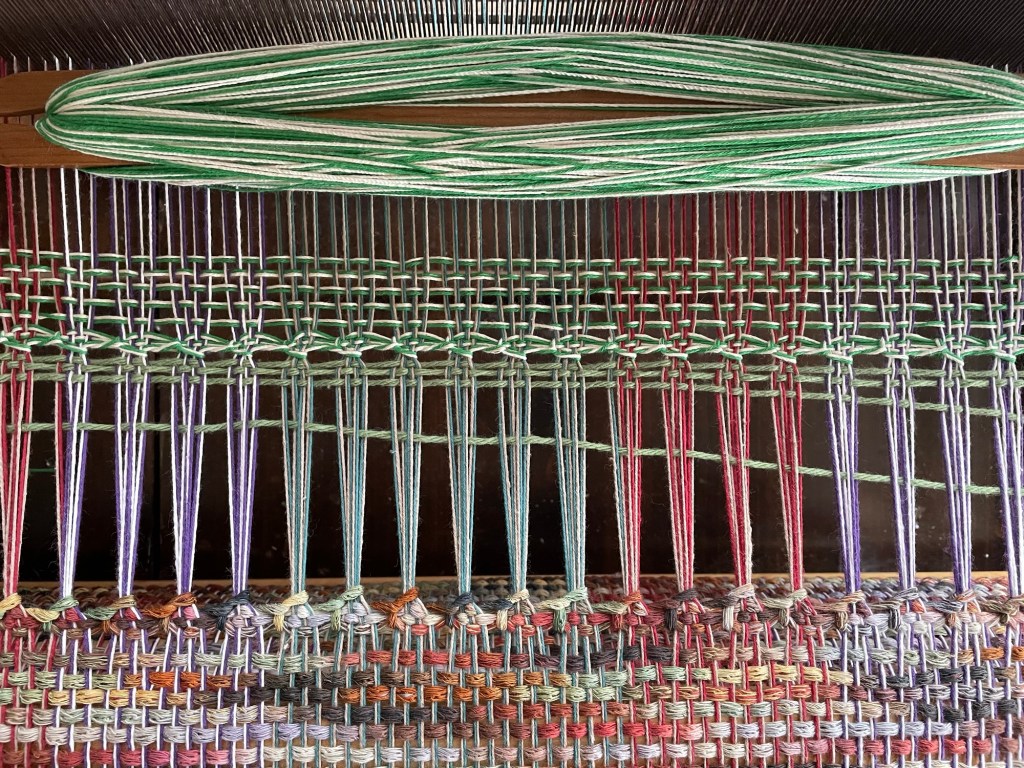

I was very interested in getting a better look at the loom once I got to the end of the warp yarn. The next photo shows the back of the loom after I had woven as much warp yarn as I could. A flat metal bar is tied on to the back beam. The warp yarn is wrapped around a length of square wood dowel, that is tied on to the flat piece of metal.

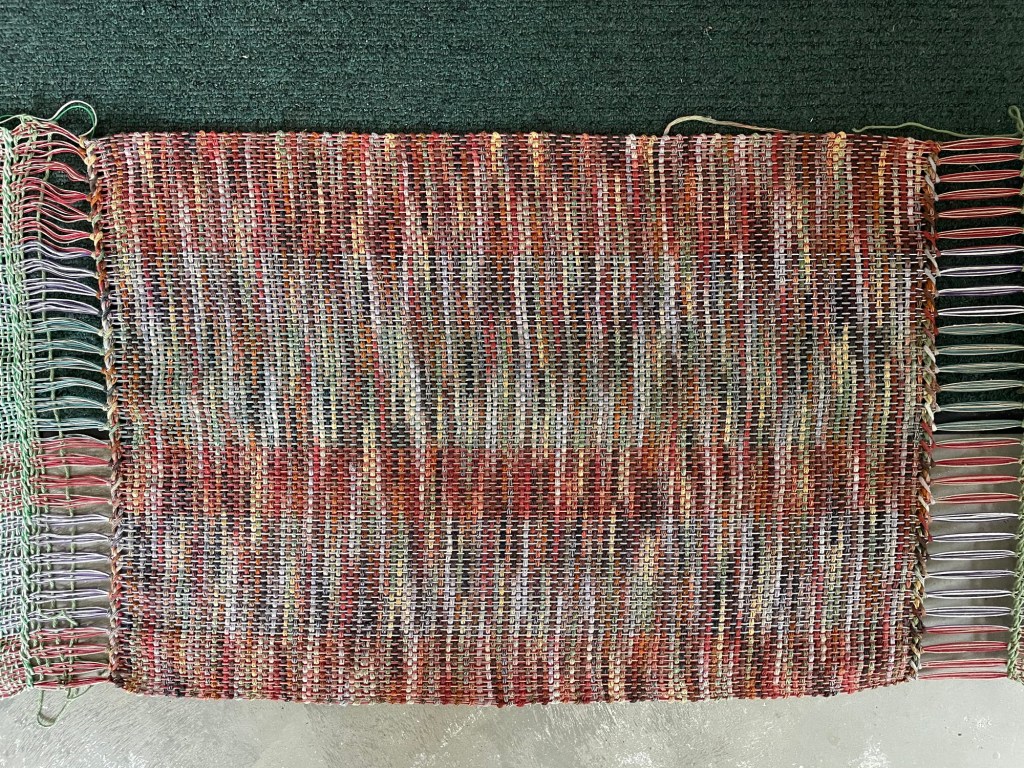

After examining what was going on at the back of the loom, I cut the warp yarns and unwound the completed weaving from the front beam. Following is a photo showing the beginning of the project where it was tied on at the front of the loom. The front beam is a thick round piece of wood that is warped. As on the back, there is a flat piece of metal tied on to the front beam that is warped and bent out of shape. A wood dowel bar is tied on to the flat piece of metal. The beginning of the rug is lashed on to the wood dowel.

It looks like the person who started this rug was also experimenting with different warp yarns. There are some rows of two different colors of some kind of flat shiny “yarn”, followed by a couple of rows of purple worsted weight cotton (something like Peaches & Creme yarn), followed by the thick stretchy rag rug “yarn”.

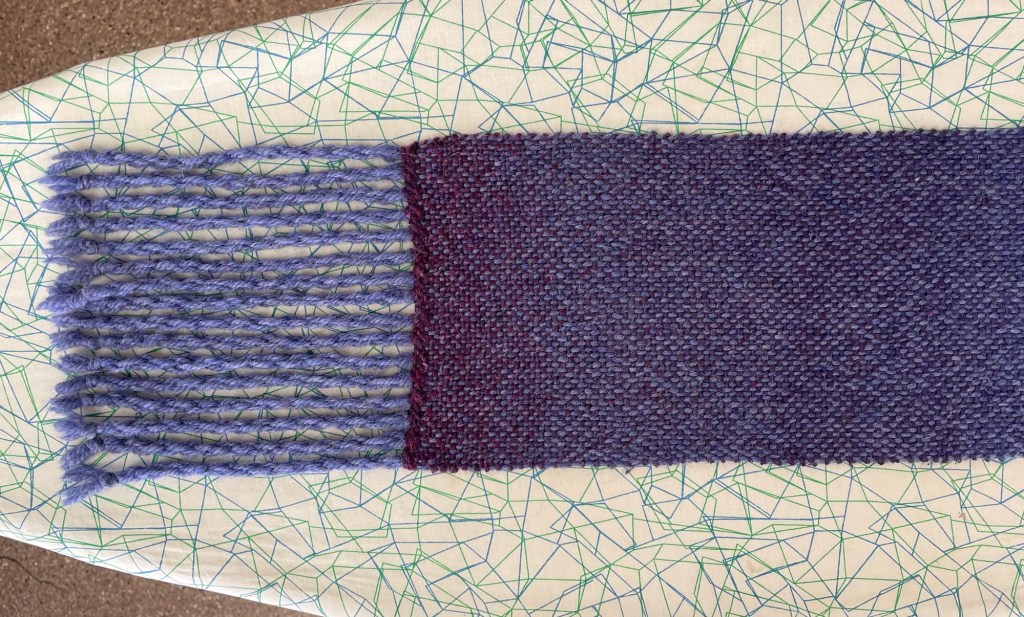

My sections of weaving are shown below, as they came off the loom. First there are rows of the green Peaches & Creme cotton, and then the Berroco variegated color chain type yarn, followed by the green and white strands of 8/4 cotton together.

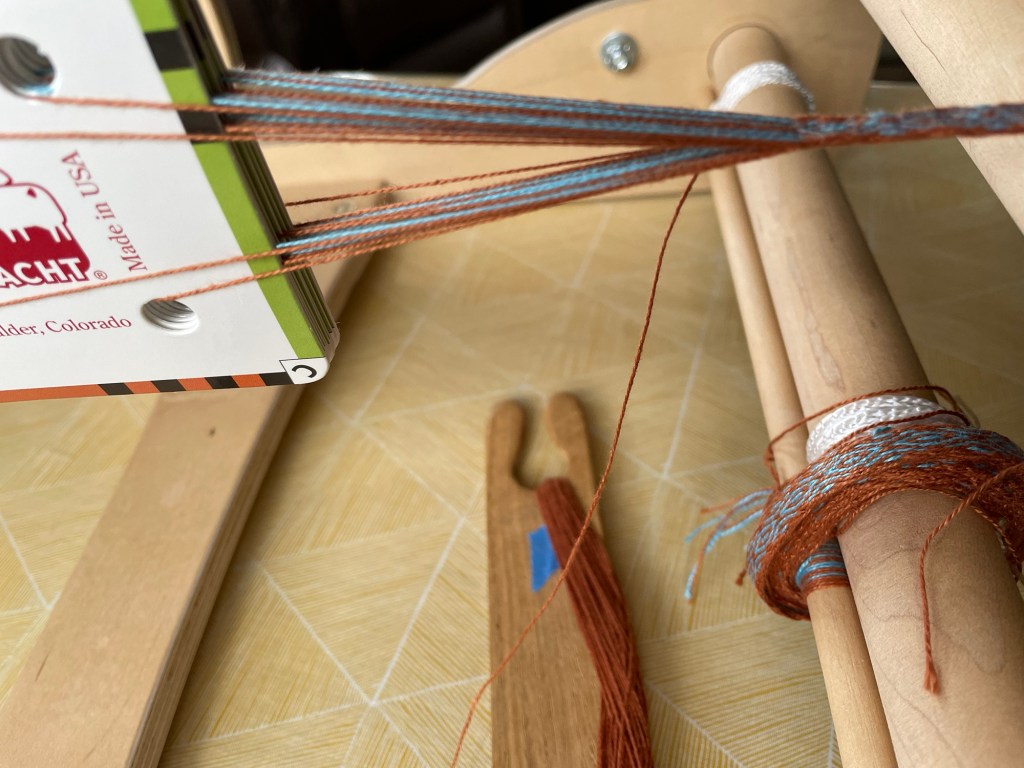

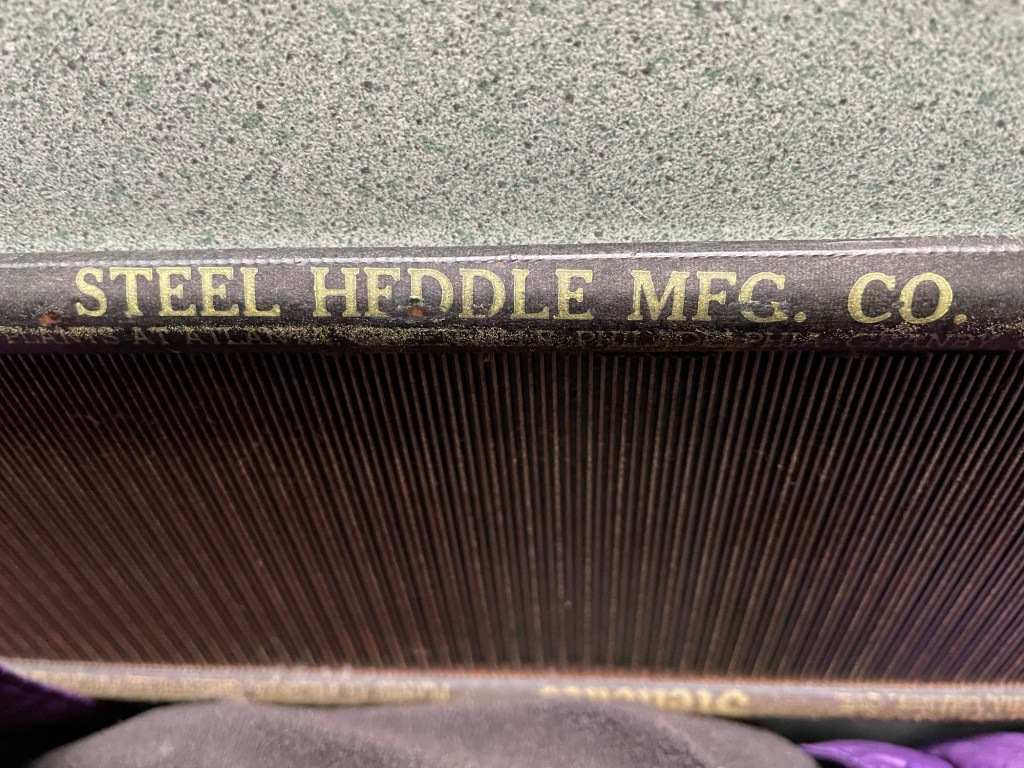

I was able to remove some screws and take off a strip of wood at the top of the reed, which allowed me to remove the reed from the loom. The reed is very rusty, but it looks like the same size as replacements available from the Schacht company.

I communicated with a woman on the Structo Loom Owners – Repair & Refurb Facebook group regarding the date that my loom might have been made. She has a list of serial numbers with their associated production dates. Between the serial number stamped on my loom and the number stamped on the reed, she is pretty sure my loom was manufactured in 1971.

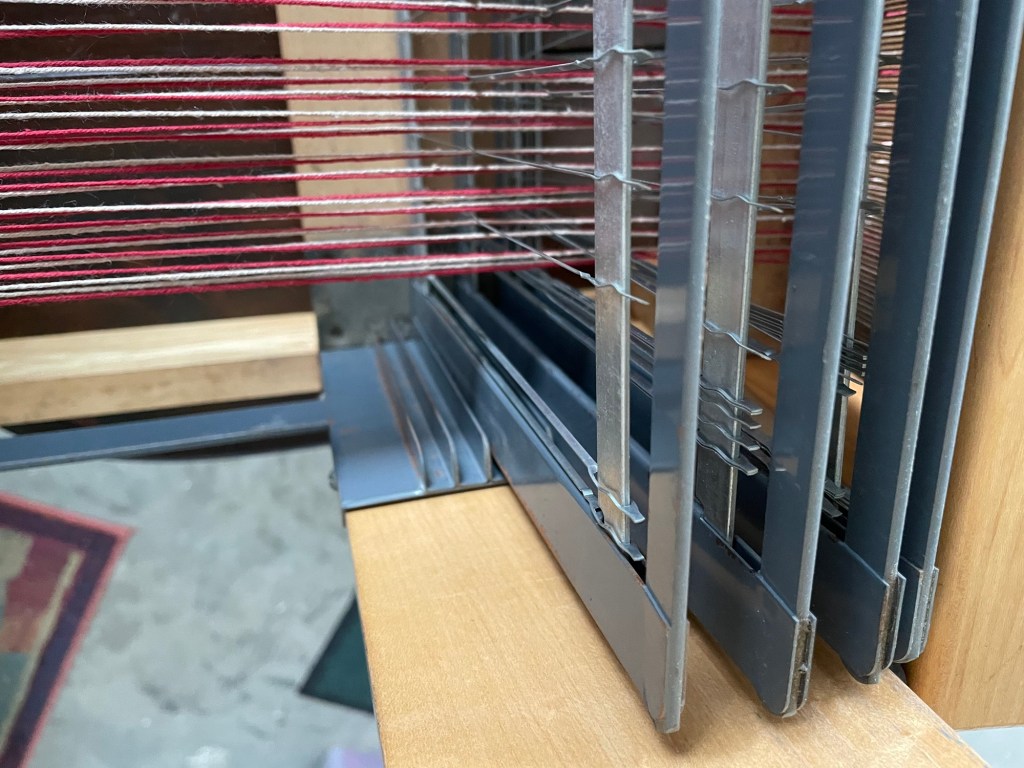

705 is at the beginning of the serial number which should indicate the model number. However information I found online indicates that it is more likely a model 740, which is an eight shaft version of the model 705. My loom currently has only four shafts but there are spaces for four more. 740 is what you get when you multiply the ends per inch of the reed by two ends per inch by the weaving width, for the maximum number of threads you could have in a warp (15 x 2 x 25 = 740).

The next photo taken from the top shows the four harnesses, and some empty slots for two more. There are spaces for two more in between the harnesses on the loom, that you cannot see given the angle of the photo.

I wove in the loose ends and washed the individual sections of weaving (except for the rug at the beginning). As expected, they shrunk some, ending up with a slightly more dense weave, but still on the loose side. I think the large section of all 8/4 cotton could be used as a towel.

I was not expecting to have any usable final product from weaving off the rest of the warp yarn that came on this vintage loom. However I did end up a table runner of sorts, and a string bag! The section woven with the Berroco weft yarn works as a runner on my dining room table, adorned with the ceramic turtle bowl and lid that my mom made. My four harness floor loom is in the background waiting for another project.

The shorter section woven with Peaches & Creme cotton could have been a loosely woven narrow towel, but I was inspired to make it into a small string bag.

Now that the Structo loom is free of a project, I plan on cleaning it and fixing it up as much as I can before using it again. That will include wiping it down with some wood conditioner, trying to figure out a replacement handle for the front beam, replacing the dowels that warp yarn is tied to at the front and back, and ordering a new reed.

Sometime in the next couple of months, we will be replacing the flooring in our living / dining area. I dread having to move all the furniture, including emptying out and moving my mom’s large china cabinet. Once that is all happening, my floor loom will be folded up and moved out of the way. My next weaving project will be on the floor loom, while it is still accessible and before the flooring chaos starts.