When my parents built their retirement home 25 years ago, they put off-white carpeting in the living room and dining area great room, as well as the main floor bedroom. Tile was installed on the floor in the kitchen, front and back hall, laundry room, and bathrooms, because my mom wanted something that would last her entire lifetime. The carpeting looked nice for a long time. It looks okay in the following “before” photos, but up close there were many stains and discolored places where people spilled food and beverages, pets had accidents, people walked on it with dirty shoes, and who knows what else happened.

One time while standing on the tile near the carpeting, my cousin dropped a bottle of red wine. Of course it shattered all over the tile, but amazingly no red wine got on the carpet. On the other hand, there were many little brown spots near the dining room table where people had slopped coffee. Lately when people asked if they should take off their shoes upon entering the house, we said “no, don’t worry about it”.

After living in this house for five years and since our elderly dog passed away, it was time to replace the off-white carpeting on the main floor. We decided to go with real hardwood floor. It is more expensive than other options, but seemed like a good value that will be worth it in the long run.

Following are “before” photos of the living room and dining area. You cannot tell how bad the carpeting looked in these photos.

In order to get ready for the hardwood floor installation, I had to move my floor loom out of the living room, which provided motivation for completing the project that was on it. You can see the loom behind the dining room table in the photo above. I figured out how to collapse the loom so it takes up less space. This can be done while there is a project on it if necessary. Folding up the back was easy, but I had to find some instructions online in order to get the front to fold in.

I have always loved and coveted my mom’s China cabinet. She bought in the early 1960’s at a thrift shop in Grand Rapids, Michigan, where we lived when I was an infant. She said that the back on the inside was so dirty she did not know there was a mirror until she got it cleaned up. My mom refinished the China cabinet, and later when they moved to this house she refinished it again. Some of my things have been displayed inside, along with some of my mom’s things.

The fact is that life has moved on, I am at a different place in my life, and expectations for entertaining have changed. In my younger days when I longed to have a nice China cabinet, we never had one. Now that I do have my mom’s China cabinet, it has looked crowded and filled with stuff I rarely use. I do love my China dishes, and occasionally I use the bone China plates, but having a dinner party stresses me out. Most of the stuff in the China cabinet never gets used and I will not miss it when it is time to downsize. Maybe my sister will have a turn with the China cabinet, unless she is also past that stage in her life too when the time comes. For now, it needed to get emptied out in order to get moved for the floor project.

We have a three season porch that was not part of the new flooring project. There is a table in the porch that got pushed against the wall, and then we moved the dining room table into the porch. I hand carried all the items from the China cabinet over to the porch and set them down on one of the tables, without needing to pack anything. It was easy and quick. It looked like a shelf at a thrift shop.

We practically filled the three season porch with furnishings and items from the living room, dining area, and main floor bedroom. It was even more crowded by the time everything was removed from all three areas.

Apparently I have not been very good at cleaning underneath the furniture. Hmmm I don’t think I have ever cleaned under the China cabinet.

In order to save money, Wayne was willing to do the prep work himself. That included removing the old carpeting, removing the carpet pad under that, removing another layer of something under that, and removing all the baseboards and outlet covers.

The space looked so different when completely empty.

Wayne rolled up the pieces of carpet and carpet pad, and loaded them on to the back of our truck for proper disposal at the city landfill, otherwise known as “the dump”.

I was visualizing a giant outdoor yard piled with junk, but instead we drove the truck inside a building. I wonder what is wrong with those chairs. Why are they not at the Goodwill? I get anxiety thinking of all the waste and what will happen to it.

The corner inside the building was piled high with bags of trash, that I assume got dumped there by garbage trucks. I do not know what happens to the trash from here.

The wood flooring got delivered to our house with some time to acclimate before getting installed.

The installers used our front porch for sawing to reduce sawdust in the house. It was 20 degrees Fahrenheit outside that day, with 20 to 30 mile per hour winds. At least the porch is covered and protected.

The installation went pretty quickly once the workers got started.

All the flooring was in place in about two days, and we were very pleased with the result.

Another trip to a different dump to get rid of more waste looked more like my vision of a dump. It was four degrees with 18 mph winds while Wayne unloaded rolls of carpeting, underlayment and particle board removed from our floors.

Kind of late in the game and in the middle of December, Wayne and I realized that while all the furniture was moved out of the rooms, we should paint the walls. This seemed pretty daunting with everything else on our schedule, including the holidays and getting ready to leave for Arizona. It was too late to get this done before the wood floor installation, but we determined we could and should paint after the floor was installed, but before we put the furniture back in place.

The walls in the living room were slightly off-white. My parents did all the interior painting themselves when the house was new. Most of the other areas in the house are painted a color. I think my mom ran out of energy after doing the other rooms.

It is interesting how interior decorating styles change over the years, just like everything else. When we bought our first house in 1985 it was a fixer-upper with wallpaper on many walls that was very hard to get off. Even a professional we hired had a hard time removing wallpaper in one room. There was brown and red plaid carpeting in the kitchen, and green shag carpeting in the living room.

My mom may have not gotten around to painting the living room walls, but white has been back in style for a few years. When our son and his wife were house hunting in 2023 many houses they looked at were almost 100% white on every surface, including all the walls, and all the kitchen cabinets and counters.

When I went to the Sherwin-Williams store to look at paint swatches, they gave me an entire folder with dozens of variations of off white. I asked them what color people are using for new builds and big remodels. The salesperson came up with a swatch right away with a color called “Accessible Beige”. We said “sure” and were done.

I like the new wall color. It goes well with the greens, blues, and red accent colors used on the main floor, including the green fireplace tiles that my mom made herself. It does not go with the lemony yellow in the kitchen, that I have never liked anyway. The next photo shows the walls painted with “accessible beige”.

We also needed to buy a couple of area rugs, one for the living room seating area, and one for the bedroom. Some people have a rug under their dining room table, but we decided to skip that for now. Looking at rugs was very intimidating for me. There are 1000’s of options ranging in price from several hundred dollars up to $10,000 for a hand knotted 100% wool rug.

That reminds me of the time when we went on an Eastern Mediterranean cruise that included a stop to see the ancient city of Ephesus. In Bible times that was a seaport, but today you have a take a two hour bus ride from the port of Izmir. Anyway, the shore excursion included a stop at a Turkish rug factory to learn about rug making. We were not shopping for a rug, but Wayne made the mistake of saying we “might” be interested in buying one. We were immediately whisked off with some other people to a different room for the hard sell. There is no way we were going to buy a rug for $8,000 or more when we had not done any research ahead of time, and did not even need a rug. They were pretty sure they could convince us to make a purchase. It was relief when we finally got out of there without buying anything.

Back to today, we did need to buy a couple of rugs. My first thought was to buy a washable rug since we live on a lake, and often have houseguests with dogs and children. Wayne was not convinced. I stressed out looking at many rug options online. It was hard to find rugs that coordinated with the green fireplace tiles, but in the end we were able to find several we both liked, in person at two different Hom Furniture stores in the Twin Cities. One of the rugs had to be ordered and was sent to the Hom store in Fargo, about 50 miles in the opposite direction from the Twin Cities.

We brought four rugs home to see what they looked like on the floor, and then returned two when we went to the “the Cities” (Minneapolis and St. Paul) for Christmas. The photo below shows our final choice for the living room rug, at the time when we were deciding between the options. The colors do not look quite right.

We pulled the painters tape off and rolled up the two keeper rugs at the end of December, the night before before leaving for our three months in Arizona.

When Wayne and I were both finally home after our crazy journey from Arizona back to Minnesota (read about that here), we immediately had houseguests to help with our extended family maple syrup operation. There was a lot going on, but it was good to have some extra people to help move furniture back in place. We have been very mindful when putting the rooms back together, trying for a cleaner look.

The green sofa in the living room is very old and faded. Wayne cannot get comfortable sitting there when watching TV. We are considering replacing it with something that has a similar style, but with a recliner function on one side. If that happens the coffee table will not work. The plaid easy chair will probably also get replaced with a recliner.

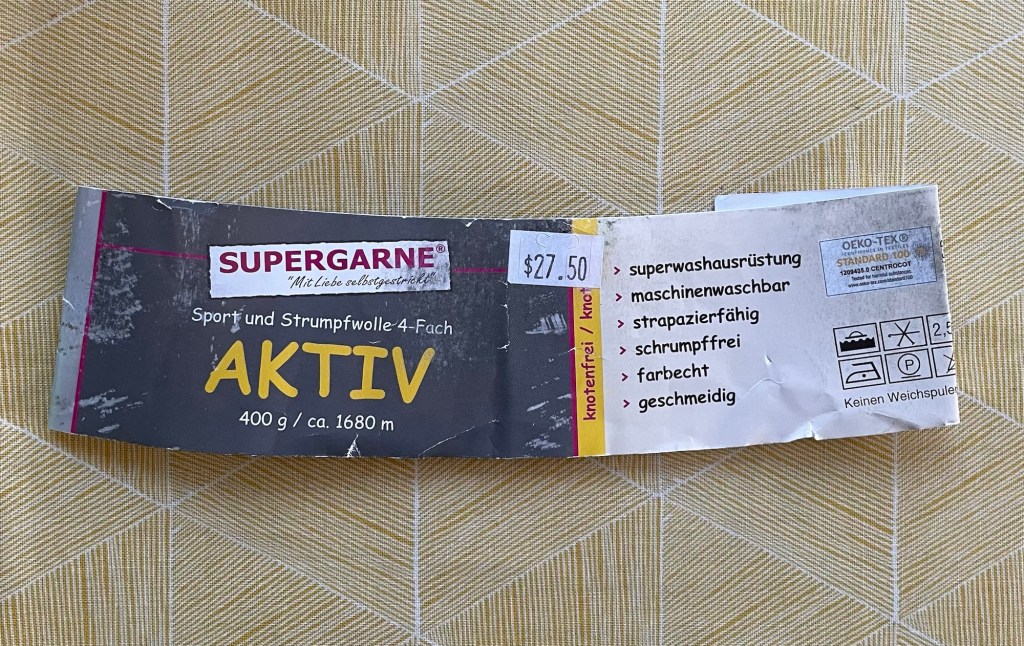

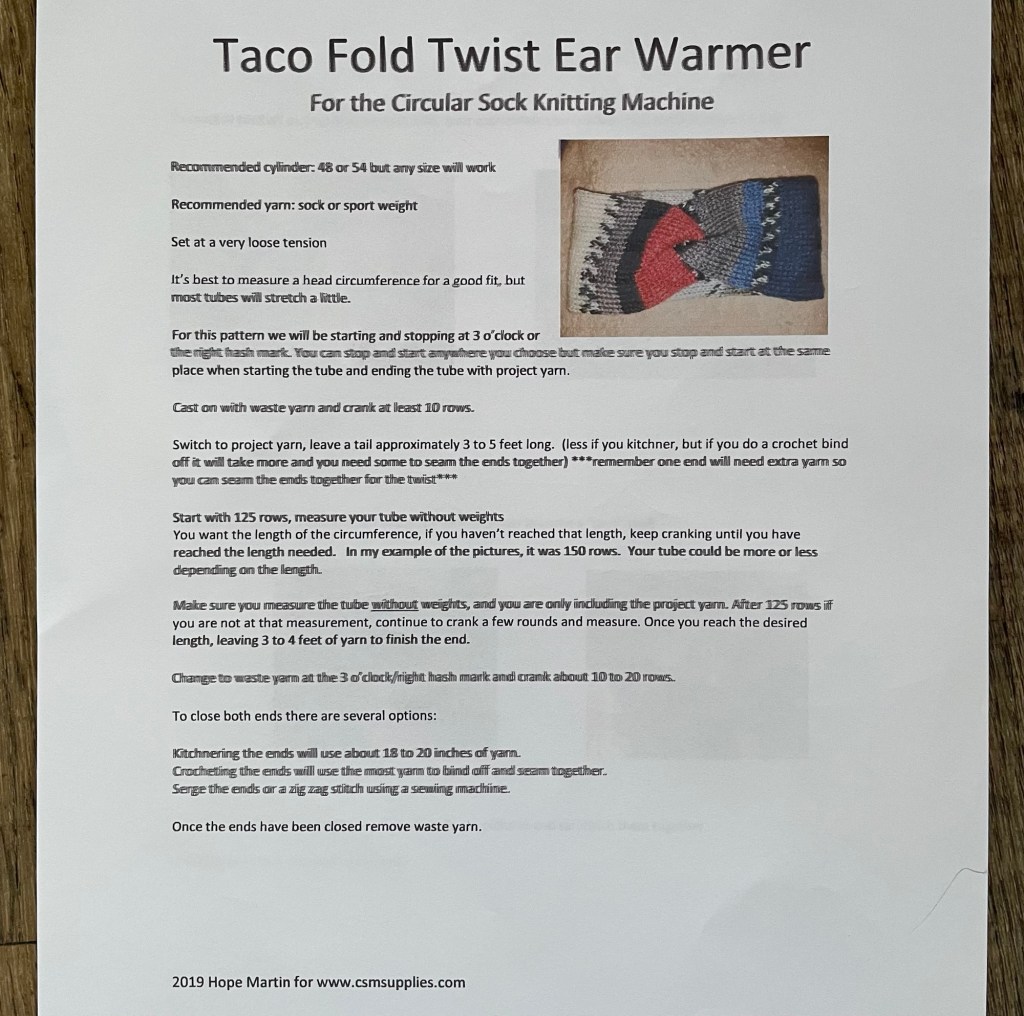

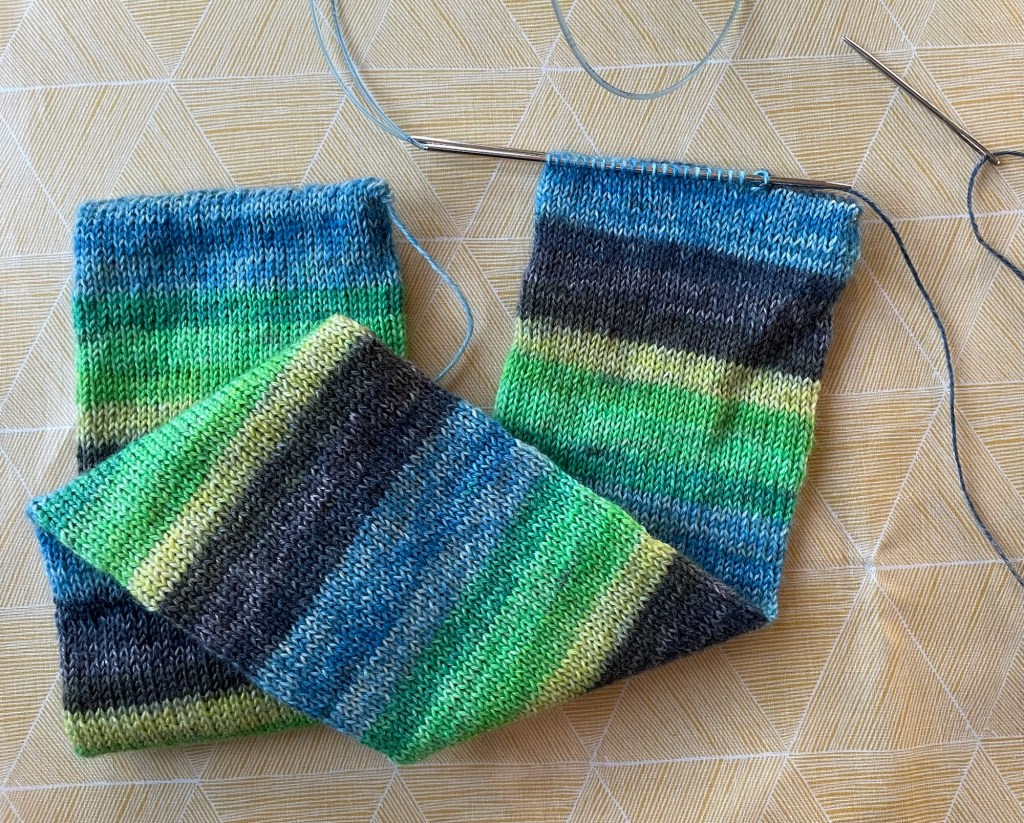

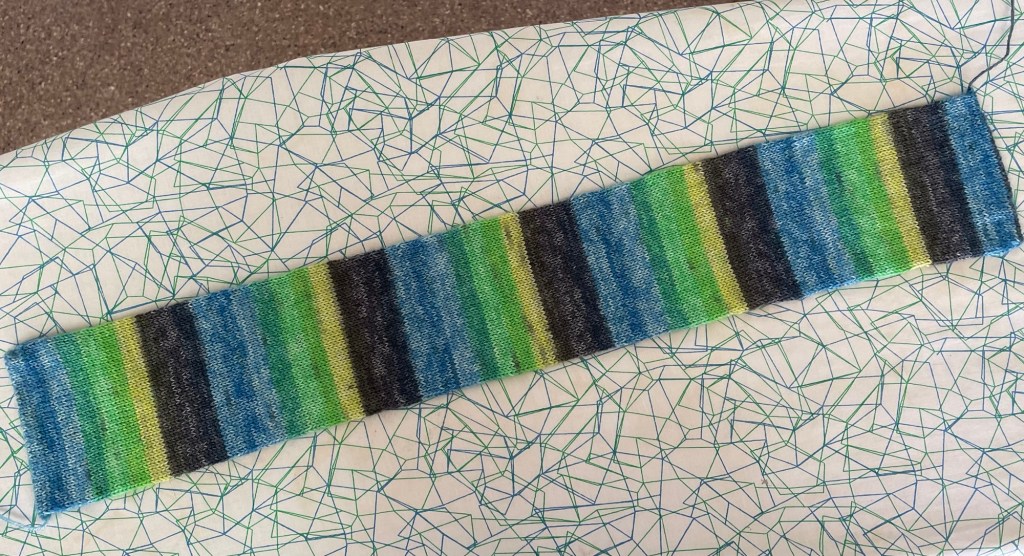

I have not put the floor loom back where it had been set up in front of the window seat in the living room. I will probably wait until I have a project to work on, which might not be until fall. Currently I am focusing on learning how to use my Circular Sock Machine, and if I have any other time for fiber craft I will use my spinning wheel or make something on my Struto Artcraft Loom. Several side chairs that had been in the living/dining area will stay in the basement or three season porch.

Most of the items from the China cabinet went back in after all, but I left some small out things that looked cluttery.

The paintings and art are not all back up yet, but in general we are very pleased with the new look. The “accessible beige” walls clash with the lemon yellow kitchen walls, so I hope we can repaint in there sooner rather than later. The kitchen sink backsplash needs to be replaced also. We will have to decide where to draw the line in other possible kitchen upgrades. It is a slippery slope.

I feel a little bad about changing the decorating and color scheme from what my mom had, but it is time for us to make the house more our own.