Over a year ago I was gifted a vintage Structo Artcraft four shaft table loom. At the time I was excited to have it, as the size is in between my small rigid heddle loom and my wider floor loom. I practiced using the table loom by weaving off the warp yarn that came on it. I wrote about getting the loom, learning some history on the brand, and my first attempt at weaving on it here.

Lately I have been considering whether or not to keep the Structo Artcraft loom. It takes up quite a bit of room, and anything I would weave on it can be made on my floor loom. However I wanted to weave an actual project on the loom before making a final decision.

Last fall I ordered some gift items from graphic artist Cindy Lindgren, a close friend of my sister-in-law. Cindy sells products with art related to specific states, Paul Bunyon, Vikings, hiking, and other fun themes. Her website can be found here, and she has some products for sale at retail locations, including MSP airport. I have a poster in my laundry room with her design of Paul Bunyon and Babe the Blue Ox having smores.

A dish towel I ordered from Cindy’s shop has art showing Norwegian Vikings holding kitchen utensils. The same art is available on other items.

I thought it would be fun to weave a set of towels on the Structo Artcraft loom using colors coordinating with the Viking theme towel. They could be given as a fun gift set. At first I thought I might have to buy yarn for this project, but after digging through my weaving yarn I already had the right colors on hand.

I was a little worried about having a mixture of fibers for the warp yarn, including 100% linen, 8/4 cotton, and Duet Cotton/Linen blend. The linen yarn is a bit thicker, the Duet is thinner. Mixing up the types of yarn could cause problems.

After looking at some ideas online, I decided to go for a plaid look in plain weave. No fancy pattern, just the pretty colors. The linen yarn was on the thicker side of the range for the 15 ends per inch reed that came with the loom. Figuring out the details involved making sure there was some 100% cotton yarn between the blocks of linen and cotton/linen blend yarn, not having too much linen yarn as a proportion of the total, and making sure the arrangement of colors looked pleasing.

I wound on half of the warp yarn in one warp chain, then realized that there was not as much of the green cotton and red duet yarn as I thought there was. I changed the pattern of colors a bit for the second half.

After measuring the warp yarn ends, I got them ready to begin threading them through the reed slots, also knows as “sleying the reed”.

Some people consider “sleying the reed” a necessary evil, but I enjoy it.

I was proud of myself for getting all 300 yarn ends threaded into the reed in one day.

The loom is sitting on an old wooden tea cart with wheels, so I turned it around for the next step of threading each end through a heddle from the back. Then I realized that I did not have enough heddles on the loom. Oh No! I had never counted them.

Not having enough heddles meant that I would either have to get more, or reduce the number of yarn ends. I was not excited about spending money on this loom, but it was not a bad idea to have a complete set of heddles for myself or another future weaver. There were options for buying a partial set or a complete set, in metal or texsolv (a durable polyester cord). I have never used texsolve heddles, but decided to try them. I ordered a complete new set, rather than ending up with a mixture of metal and texsolv heddles.

The project was on hold while I waited for delivery of the order. Meanwhile, we had our son and daughter-in-law for the weekend, with their two year old, Blair, and two month old, Nora. We cleaned the house and childproofed for small visitors. Within an hour of their arrival, the house was chaos with toys and stuff everywhere, LOL. It was super hot out with high temperatures in 90’s Fahrenheit and heat index over 100 degrees. We spent time at the family cabin beach in the earlier part of the day before it got too hot. Blair got to see a turtle swimming in the lake, and Wayne caught a fish for her off the end of the dock. There is a video of Wayne with the fish that Blair has since requested to watch dozens of times.

Blair got a boat ride in Wayne’s small fishing boat, and the next day we all went on a pontoon boat ride. It was a great weekend and we looked forward to their next visit.

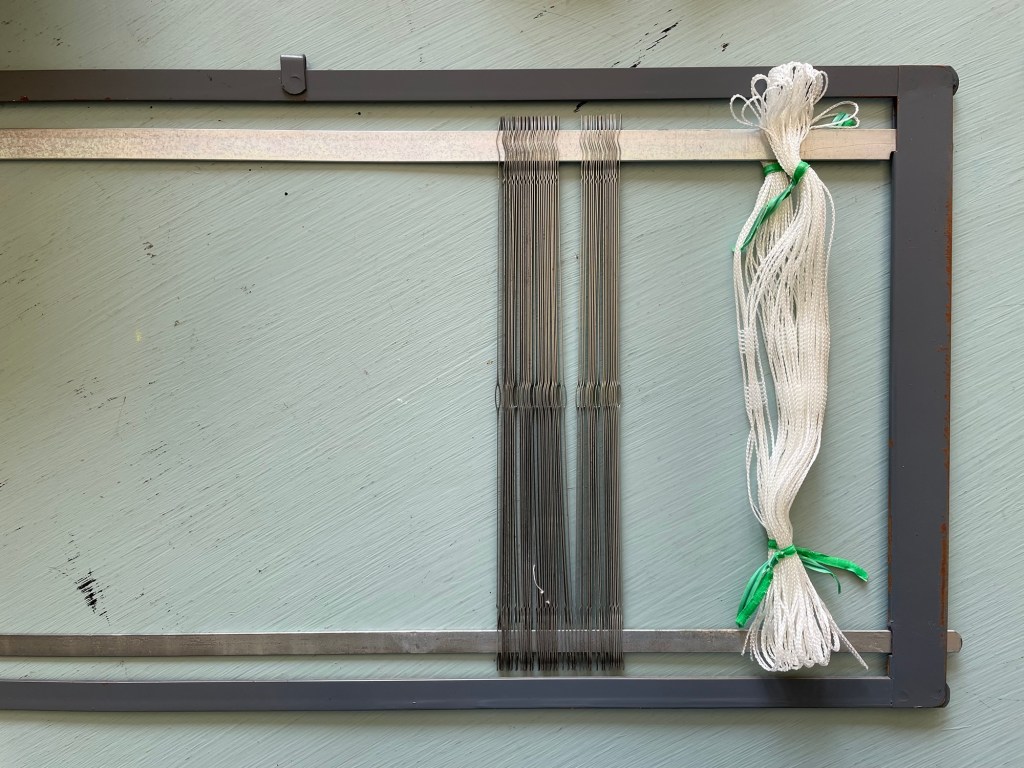

After we had gotten the house back in order, my texsolv heddles arrived in the mail. They seemed to be too short, even though had I measured very carefully. It is hard to tell from this photo of the original metal heddles next to the new texsolv heddles.

I considered moving the project to my floor loom. It was not too late for that. However I decided to first bring one of the harnesses (frame that the heddles are hanging on) with the original metal heddles to show Torri, my experienced weaver mentor in Fergus Falls. After taking the twist ties off and actually putting one bundle of heddles on the harness, we realized they did in fact fit. Back at home I spent the evening getting the harnesses off the loom, removing the old metal heddles, and putting the new texsolv heddles on the harnesses.

The new heddles fit snugly. They do not rattle and clank against each other like the metal version. They do not slide as easily as the metal heddles. I am not sure if that is normal, or if they are fitting tighter than they are supposed to. This is a vintage loom no longer in production, so possibly the standard sizes available are not exactly right.

Threading the yarn ends through the heddles was a slow process for me. The ergonomics were not ideal. When sitting on a stool, I could not see the yarn ends coming out of the reed. Standing, I could see but had to lean over. I made sure to take breaks.

After project was completely warped, I wove a couple of rows and worked the hem stitch at the beginning of the first towel.

After weaving for only a few inches, something became horribly wrong with the tension and I did not know what to do. I had talked to Torri about coming over sometime to see this loom, as well as my circular sock machine. It was Sunday, so her shop was closed. Luckily for me she was available and willing to stop by my house after she left an event she was attending.

Torri figured out what was wrong immediately. In the photo below you can see a wood dowel with the yarn ends tied on to it, and a white band zig zagging between that and a metal bar below that is not visible. The “zag” at the right end of the dowel had fallen off, so the dowel was not under tension at that end. DUH, I felt so dumb for not noticing that myself, but I was relieved the problem was easy to fix. She made a couple of other adjustments on the back.

After the weaving was back in shape, Torri enjoyed watching me make a sock on my sock machine, mostly without any mistakes. I sent a jug of our family made maple syrup home with her as a thank you. I was able to continue weaving rows on the towel after she left.

Throughout the weaving project I had tension issues. I am going to blame it on the vintage loom, but there could have been some user error too. As I wove and wound the fabric on to the front beam, it was crooked. If I tried to fix it, then the warp yarns were too loose on one side. I could make small adjustments by beating the rows a bit tighter on that side.

One thing that bugged me, but may not have been an actual problem, was that sometimes when I raised harnesses two and four as in the next photo, they were crooked. I kept on going without trying to figure it out.

Another thing that probably was contributing to my problems is visible in the photo below. On the back beam you can see the metal bar that is connected to the wood dowel by the zig zagging white band at the beginning of the warp. It is off center and not laying flat.

In the following photo you can see how the weaving is crooked, by comparing where the rows line up with the wood on each side.

Another thing that was happening was that when beating a row, it did not beat evenly. If I beat with the reed a second time it would even out.

When I had finished weaving both towels and removed them from the loom, I found some floats, where one of the weft yarns missed some of the warp yarns.

I had to fix the floats by manually weaving a second piece of yarn over the same section. Following is a photo showing where I fixed a different float.

Following are photos of the two towels off the loom. They looked better than I expected given the crooked weaving and other tension problems. For the first towel I wove the weft rows matching the pattern of the warp yarns.

For the second towel, I wove four inches each of the seven different yarns.

I knew that using different types of yarn in both the warp and weft would affect the look of the fabric and result in different take-up and shrinkage. The thicker linen yarn caused those sections to bow out a bit. The fabric seemed very stiff. I had been worried that using the 15 ends per inch reed would make the fabric too dense, but visually it seemed right.

After fixing the floats, weaving in ends, and running the towels through the washing machine and dryer, they did not feel too stiff. They felt nice and substantial. They were also uneven. The towels are not exact rectangles, no surprise. The different thicknesses and textures of the yarns made it interesting and camouflaged some of the imperfections.

One thing I like about making towels is that even if they are not symmetrical and have imperfections, they are still functional. They do coordinate nicely with the Cindy Lindgren towels.

I love the way each of the colors interacts with the other colors as they intersect. I would never have thought of putting olive green and turquoise green together, but I like that combination a lot.

I wanted to finish this weaving project and publish a blog about it before we are out of town for two weeks. We are getting ready to leave for a trip to Yellowstone National Park and the Grand Tetons with our 5th Wheel Trailer. Some people warp enough yarn for 4 or 6 or more towels. Given I am always nervous about tension problems, I prefer to measure a shorter warp. In this case, I was glad I only had enough for two towels, and with the challenges I had, I am glad to be done.

I was frustrated with some of the problems I had, that I am going to blame more on the loom than my skill level. I should clarify that this loom is actually in pretty good shape for being 50 plus years old, but I do like having good equipment. This brand of vintage loom is not made any more, and thus parts are not available for restoring it to perfect condition. I do not really need it. If I did want to have a table loom, I would rather buy a new one or a newer used model that is still in production.

I was considering selling the loom, but I have a better offer. Torri has two flatbed knitting machines still in the boxes that she has never used, and does not expect to use. She is going to trade me the Structo Artcraft table loom for the two flatbed knitting machines. I don’t really have time to go down yet another rabbit hole, but I am interested is seeing how flatbed knitting machines work and what I could make with them. Like the circular sock machine, they can knit something up a lot faster than hand knitting. And it turns out that the School of Sweet Georgia just came out with a class on flatbed knitting machines. I watched part of it already. The instructor is Barb Barone, of Yarniversity by River City Yarns. Barb is very patient and calming to listen to. She is the “Bob Ross” of knitting instructors.

Meanwhile I am assembling a couple of projects to bring on the Yellowstone trip, that are portable for working while on the road and when we get there. I am attempting to make some knitted and felted slippers (that I thought would be done a month ago), and I am bringing a narrow four inch wide loom to practice band weaving. After my crazy schedule so far this summer, I am looking forward to getting away for a couple of weeks.

I think you gave that vintage loom a fair shot. And it seems the trade you made is a happy deal for both of you. I look forward to reading about the flat knitting machine. The towels you made are very nice. I hope you have a great time in Yellowstone and Grand Tetons.

LikeLiked by 1 person

Thank you. I think it is a good trade too and I look forward to opening those knitting machine boxes. Meanwhile, it will good to get away for a couple of weeks!

LikeLiked by 1 person

It sounds like you gave the loom a fair try. It just wasn’t a good fit for you. The trade you made sounds very interesting.

LikeLiked by 1 person

I agree. It seems like my weaver friend and I will both benefit from a trade. I look forward to opening the boxes to see what is inside, in the fall, after we get back from our trip.

LikeLike

I love those towels! Such pretty colors and I would love to try a loom someday.

LikeLiked by 1 person

Thank you! I encourage you to try weaving. A rigid heddle type of loom is a good place to start. I could have made these towels on a rigid heddle loom, since they are plain weave, but mine is not wide enough. However they do make them wider than the one I have.

LikeLiked by 1 person

I will look to see if our local Art Center does anything like this!

LikeLiked by 1 person

The colours are beautiful and match the Vikings so well! I also love threading the loom (providing I’m not in a rush!). I originally learnt to weave the Saori way which actively celebrates and makes features of ‘faults’ in weaving as a way of showing that a textile has been made by human not machine, so I’m quite fond of imperfections in weaving 🙂

LikeLiked by 2 people

Thank you! We know it is hand made when there are mistakes!

LikeLiked by 1 person