My mother’s family has a tradition of making maple syrup on a large scale. My grandfather had a big operation in the years following WWII, and up until the 1960’s when my uncles were not able to help any more. In the early 2000’s some of the next generation bought new equipment and built a syrup shed in the woodlot property near the family cabin, using wood from trees that had fallen after a big storm.

At the beginning of this rebirth of family syrup making, people were enthusiastic and eager to participate. Since then it has been harder to get enough helpers at the right time, and usually most of the work is done by a smaller number of people. The exact process and equipment has evolved over the years, and some years have been more successful than others for various factors, including unpredictable weather.

For a number of years plastic tubing was used for collecting and transporting sap to a tank outside the syrup shack. That system has problems including a lot of maintenance in the off season, and the lines freezing overnight stopping the flow of sap. It was decided to go back to buckets for sap collection, and to make syrup every other year instead of annually.

I wrote a blog post in 2021 which can be accessed here, with quite a bit of information about our family maple syrup operation, so I won’t write all the history and details again. I used a few photos here from that earlier post, because they were helpful in showing a complete picture of the process.

This spring, conditions were excellent for syrup production with weeks of temperatures below freezing at night and above freezing during the day. There was one dumping of about 10″ of snow near the end of March, but it melted quickly.

The process began in the middle of March when my cousin and his wife, and some other helpers, tapped the trees and connected plastic tubing from the spile (the spigot thing on the tree) to the bucket sitting on the ground. I was still in Arizona at that time, so missed out on this activity and do not have any photos. Approximately 240 trees were tapped.

There was a big group of syrup helpers the first weekend of April. Wayne had just arrived home after being stuck in Grants, New Mexico, for a week, on the way back from Arizona (see blog post here). My sister and her husband and some friends lodged at our house that weekend, near the cabin and woodlot property. I had made it to the Twin Cities after flying from Albuquerque to Minnesota, but was on call in St. Paul waiting for the birth of our second granddaughter. When we knew the baby was coming on Sunday morning April 6, Wayne drove three hours from our house to St Paul, straight to the hospital to meet Nora. After spending a few days in the Cities, we drove back home together, my first time at home since the end of December when we left for Arizona.

I had about a day and a half to regroup and prepare for more company for the final weekend of syrup making, when the sap would be cooked into syrup and bottled. My sister and her husband came again with the same friends. A friend of mine came to help, who had wanted to experience syrup making two years ago but was not available that time. Sheri turned out to be a rock star syrup helper able to carry two five gallon buckets of sap. I could barely lift one.

The sap gets dumped from the buckets into a container on the back of the truck that has a screen to filter out any debris.

From there the sap gets pumped into a storage tank on the truck, as seen in the following photo from two years ago. The weather was nice two years ago also.

When there is as much sap in the tank as the truck can handle, the sap gets pumped into another bigger tank on the outside of the syrup shed.

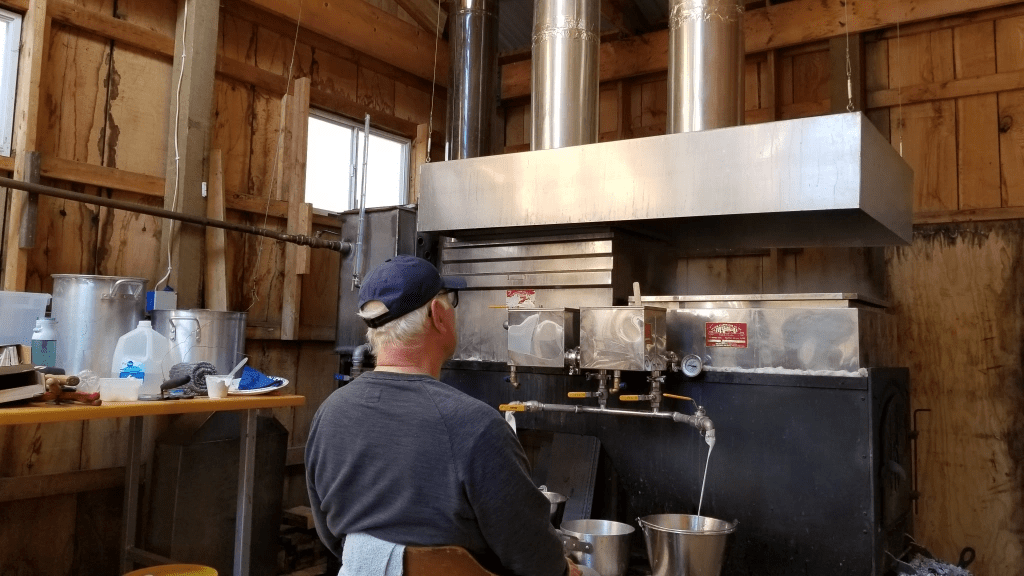

The sap then goes from the tank outside of the building through a pipe into a “pre-heater” container on the inside, and then into the evaporator. Someone, usually my uncle or cousin, monitors the evaporator. The following photo showing uncle Mark in front of the evaporator is from two years ago.

There is invariably a certain amount of down time waiting for someone to go get something or fix something, and for the sap to get up to the right temperature. Sheri and Mark are not complaining about sitting around in the next photo. In the background are upside down plastic jugs of syrup that have already been bottled.

When the temperature of the sap reaches 180 to 200 degrees Fahrenheit, it is syrup and is released into metal buckets.

After coming out of the evaporator and before being bottled, the syrup goes through three more pieces of equipment getting filtered and pasteurized.

The following bottles are ready to get filled with syrup.

The evaporator is fueled by wood. A lot of wood.

Part of the syrup making experience is preparing wood for use in the evaporator. Someone with the appropriate skill level uses a chainsaw in the woods to cut downed trees into manageable sizes to load on the truck and bring back to the shed. Other tasks include operating the wood splitter.

I helped with splitting wood on Saturday afternoon. When a big pile of logs to be split was almost down to nothing, I was ready to move on to another task. But no, another big load of wood was delivered.

Stacking the split wood in the syrup shed is another one of the tasks for the weekend.

The woodlot property does not have a well. Water is hauled to the site and stored in a big tank set up high inside the building, taking advantage of gravity for water to flow through hoses and a faucet into a utility sink inside the building.

There is no bathroom on site. There is an outhouse which looks cute on the outside.

The inside is not great, but if you have to go it is better than driving a mile back to the house. Someone found a piece of “interesting” wood art that is now displayed inside the outhouse.

On Saturday at mid day there was a pancake brunch in the woods. Liz is getting some just made syrup for the pancakes.

The sap flow was so good this year that there was not enough time to cook it all while people were there to finish up the processing. I was told that as many as 200 gallons of sap was dumped out of buckets into the woods.

Some people were extremely sad to see this happen, including my sister who took a bucket of sap home to the Twin Cities in her car. She left a bucket of sap in our garage. “Maple Water” is a thing, that may have some health benefits. It has electrolytes, antioxidants, and minerals. You can drink maple sap straight or use it for making coffee or oatmeal or other things. After boiling it for about five minutes for food safety, I put some of the sap into plastic pitchers store in our basement refrigerator. I had to dump some of it out due to not enough room in the refrigerator. I have used some for tasty oatmeal and cappuccinos.

After all the syrup had been cooked and bottled, the buckets, lids, caps and tubing had to be washed.

The washing task can be pretty miserable if it is windy, cold, snowy, or raining. Any and all of those conditions are common in the spring. Luckily it was pretty warm and dry outside this time for the cleaning crew.

This year a bumper crop of 58 gallons of maple syrup was produced, with workers including Eriksson family members and friends. That is GALLONS of syrup. At a 40 to one ratio of sap to syrup, that is about 2320 gallons of sap.

After all the bottling was done, the inventory got delivered to our house for storage. In addition to doing the family property LLC bookkeeping, I manage the syrup inventory. Following is a photo of only part of the bottled syrup in our basement. The complete inventory was composed of 41 glass quart jars, 129 plastic quart jugs, 101 plastic pint jugs, and 47 half pint plastic jugs.

Some of the syrup is given complimentary to the workers, based on how many hours of labor were contributed. The rest is sold to family members and friends. It is cheaper to buy it at Costco, but it is fun to use the stuff that we made ourselves and know the quality is good.

Paying for the syrup we just made ourselves is similar to buying a sock machine and yarn for cranking out socks. There is more money spent than saved. Syrup making involves a lot of time and effort. However, assuming the weather is not miserable, working together outside with cousins and friends is fun bonding experience.

It does sound like a lot of work, but fun at the same time.

LikeLiked by 1 person

True. Sometimes we complain about having to do this. We can decline to participate but since we live nearby it makes sense to help. Assuming the weather is not miserable, it ends up being fun and a good experience.

LikeLike

It does look like a lot of work!

I buy maple syrup made locally here in Connecticut and it is so superior to store bought. So delicious! 😍

LikeLiked by 1 person

And then there are people who don’t know the difference, and eat the fake stuff made out of corn syrup.

LikeLike

Oh, Meg, that was SO interesting! Really makes me appreciate pure maple syrup! Do you come to the Cities very often to see the new baby?

Joanne

LikeLiked by 1 person

Joanne,

Yes we have made several trips to the Cities. Usually they are short and we are trying to run errands and spend as much time as possible with James and Kelsey. I am looking forward to having them come up to see us at the lake. Probably in the middle of June.

LikeLike

What a neat thing to do! With all the work, it does seem like doing it every other year is a good idea. Does the syrup inventory last for two years? With all of my hobbies – and I suspect most, it’s not about the money. It’s the joy of creation. I think this would also be educational for young people.

LikeLiked by 1 person

The inventory does last for 2 years, which is another reason not to make it every year. After this huge batch, we may not need to make any for three years! It lasts a long time unopened, but once you open a jug it needs to go in the fridge.

LikeLiked by 1 person