In the spring of 2024 after we got back from Arizona, I wove a set of dish towels on my floor loom (blog post with photos is here). When I was finished there was a lot of warp yarn left that I did not want to waste. I tied the yarn ends loosely so they would not get accidentally pulled out of the reed before I decided what to do with it. It sat there like that with many people and little children and dogs brushing past all summer.

In September, I finally had time to work on another floor loom project where I tied the warp yarn on to the ends left from the other project. I could have just pulled all the extra warp yarn off and started over, but it seemed wasteful. Tying ends on, rather than starting over, means you avoid the time consuming process of threading all the 317 ends through the reed and the heddles, assuming you want to use the same pattern. Also, the new project will have less warp waste. I still had to tie each new end on to an old end, and work them through the slots in the reed and the holes in the heddles to the other side.

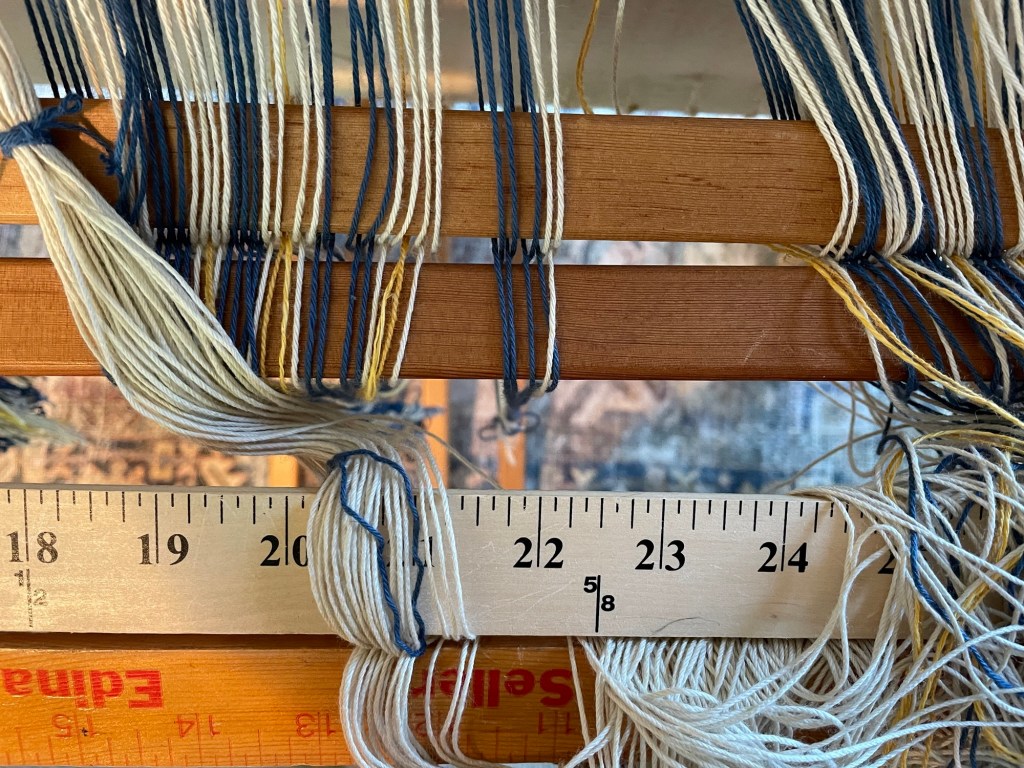

The previous project had warp yarn with stripes of blue and off white cotton, and a few yellow stripes of cotton/linen blend yarn. The new project had warp yarn all the same off white 8/4 cotton. I was interested in seeing how the same pattern would look with only one color warp yarn, and only one color weft yarn. Following is a photo with the new warp yarn measured out and waiting to get tied on to the previous warp yarn ends.

This post has a lot of weaving details, so I expect some (most?) readers will skip over the text. Scroll to the end if you want to see the final completed towels without all the steps to get there.

I researched ideas for tying the new warp ends on successfully. The most important tip I found was to use two sets of lease sticks to preserve the “cross” in the existing warp ends and in the new warp ends, since I had two ends per slot in the reed. I only have one set of lease sticks, so I used two yardsticks for the second set. The next photo shows the two sets of lease sticks with some of the ends tied on.

After all the ends were tied on and I removed the yardstick lease sticks, it looked like a mess.

It was tricky to pull all the knots where the new ends were tied on through the slots in the reed and the holes in the heddles. The following photo shows the back of the loom after all the knots were on the other side, and I was ready to wind the warp yarn on to the back beam.

I had measured out enough warp yarn for three towels. The photo below shows all the yarns I used for the project, including the warp yarn off white 8/4 cotton on the left, three colors of Gist Duet cotton/linen blend weft yarn for three different towels, and yellow 8/4 cotton on the right used for a forth smaller towel.

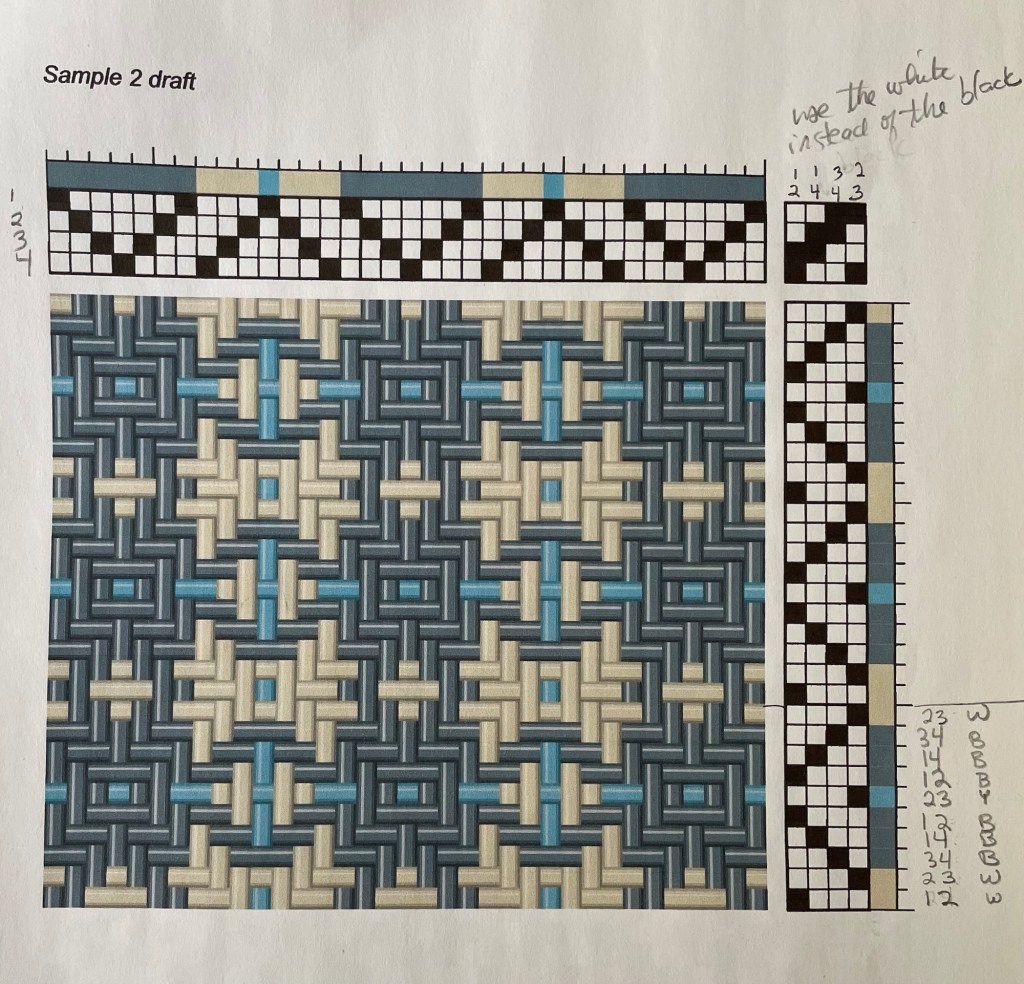

Following is a photo of the pattern used for the first towel in this set, with multiple colors, the way I made it the first time in the spring.

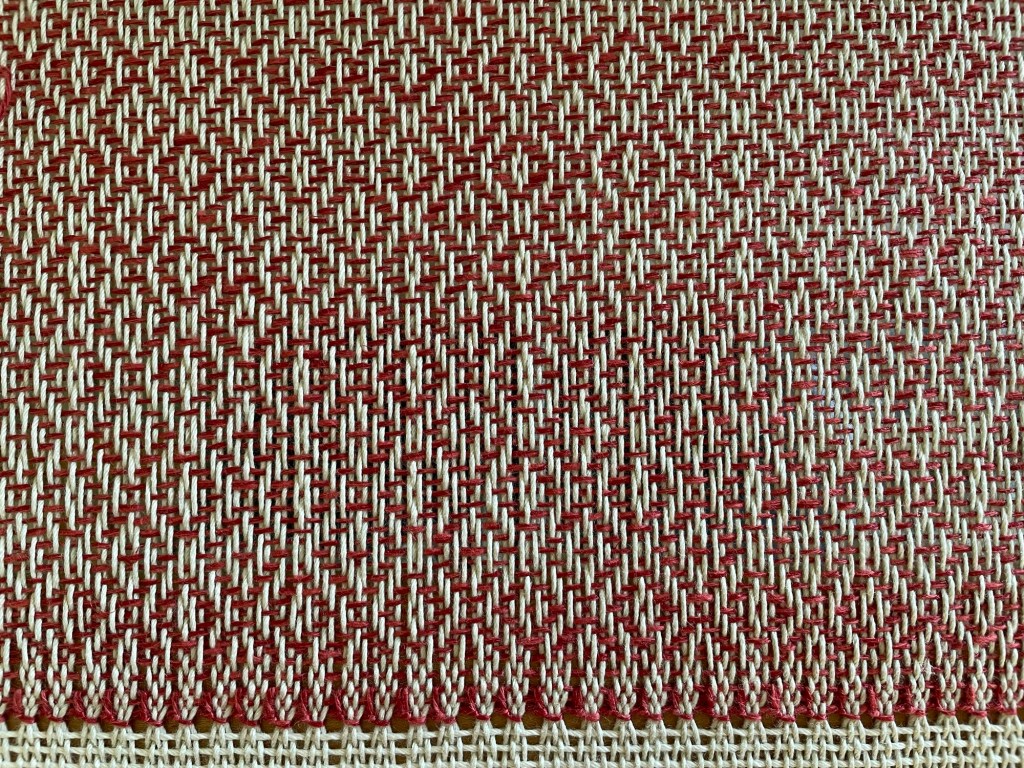

The next photo is the first towel in progress on the loom, using the pattern above, but with off white warp yarn, and red Gist Duet cotton/linen blend weft yarn.

After finishing the red towel and weaving some spacer rows, I started the next towel using weft yarn of blue Gist Duet cotton/linen blend. The treadling pattern is slightly different. The area in between the two towels will become fringe.

After the blue towel was the right length, I started a new one with a different easier treadling pattern using Gist Duet warp yarn in yellow.

When I finished weaving the red, blue and yellow towels, there was still some warp yarn left. It was not enough for a whole towel, but it was enough to do some sample weaving using a different weft yarn for comparison. I used the same treadling pattern as the yellow towel, but with weft yarn of yellow 8/4 cotton instead of the Gist Duet cotton/linen blend. The 8/4 cotton is a bit thicker, so I wanted to see how those two weft yarns compared with the same warp yarn and ends per inch.

Once the knots rolled forward from the back beam and came close to the heddles, they got tangled up and it was hard to get a good shed (the space where the weft yarn goes across to weave a row). I had to get all the knots back through the holes in the heddles and through the slots in the reed again, this time from the back to the front. I wove some rows with big floats where warp yarns were not in the right place. I was not too worried as this was just a sample. I figured out that this problem could mostly be fixed if I stuck my hand in and separated the warp yarns from each other before each weft row.

After I wove as far as I could, I hem stitched the end and cut the completed weaving off the loom. There was still all that warp yarn waste from the spring project, the same as before. This time I cut it off as I had something else in mind for my next project, that would require a different pattern using a different reed with more ends per inch. After removing all the waste warp yarn I saved it, what for I don’t know what. It is a lot yarn that can be used for something.

Following are photos of the completed towels after I wove in loose ends, and washed and dried them in the washing machine and dryer. It was amazing to me to see the difference between the corresponding towels from the spring, this time using the same pattern but without the stripes.

The first towel has all off white for the warp, and all red Gist Duet cotton/linen blend for the weft, shown next to the towel with the exact same pattern but with stripes and a different combination of yarns from last fall. It is hard to believe they are the same pattern.

The next photo shows the blue towel and the corresponding striped towel with a slightly different treadling pattern and different yarns. There are five white stripes in the towel on the right, compared to only three white stripes in the towel above (among other small differences in the treadling pattern).

The next photo shows the new yellow towel with a zig zag pattern on the left, next to another towel I made quite awhile ago with a different zig zag pattern going the other direction. The towels have the same two yarns (8/4 cotton warp and Gist Duet weft). The difference, beside the pattern variation, is that the new towel on the left has 16 ends per inch, which is denser than the older towel made with 12 ends per inch.

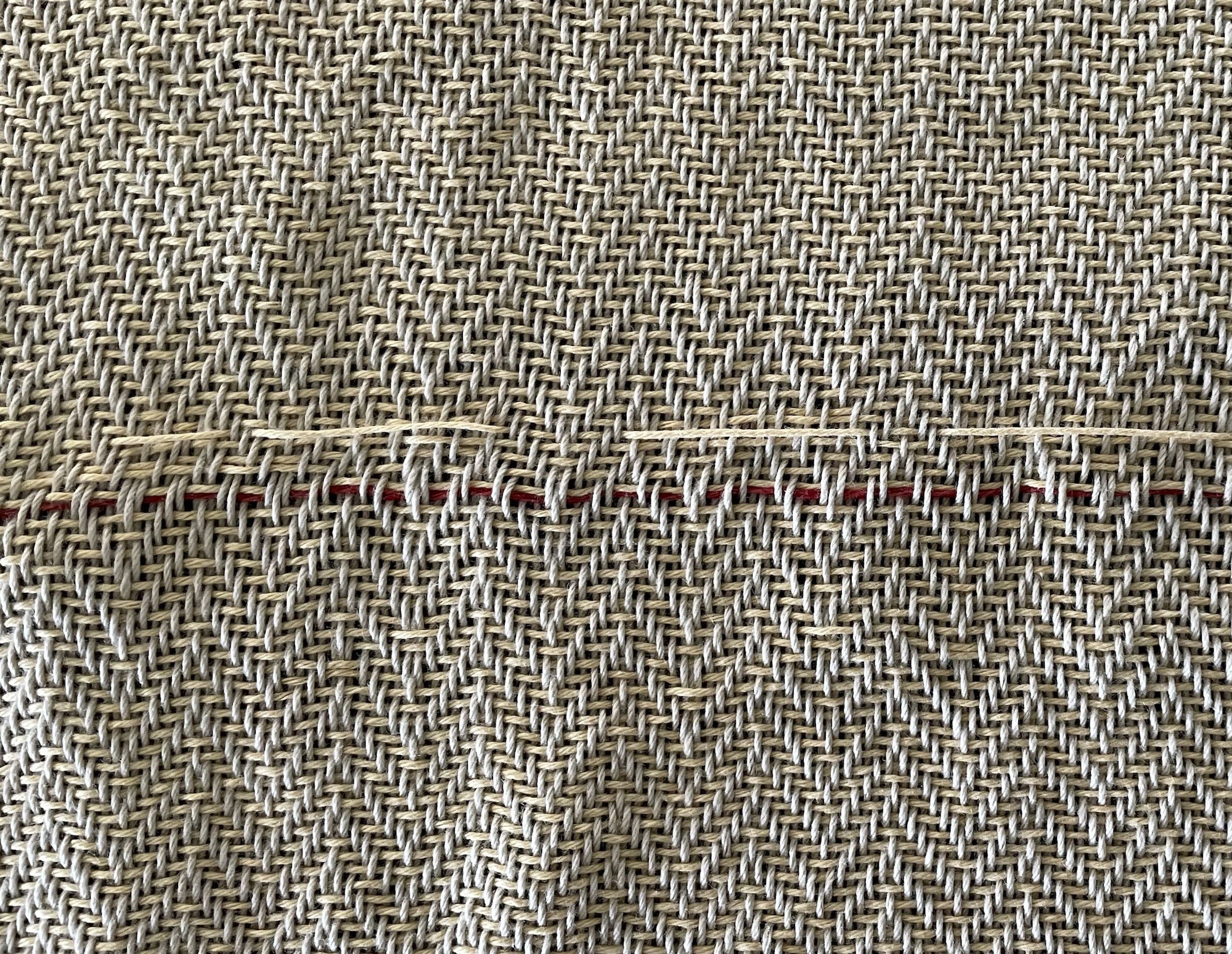

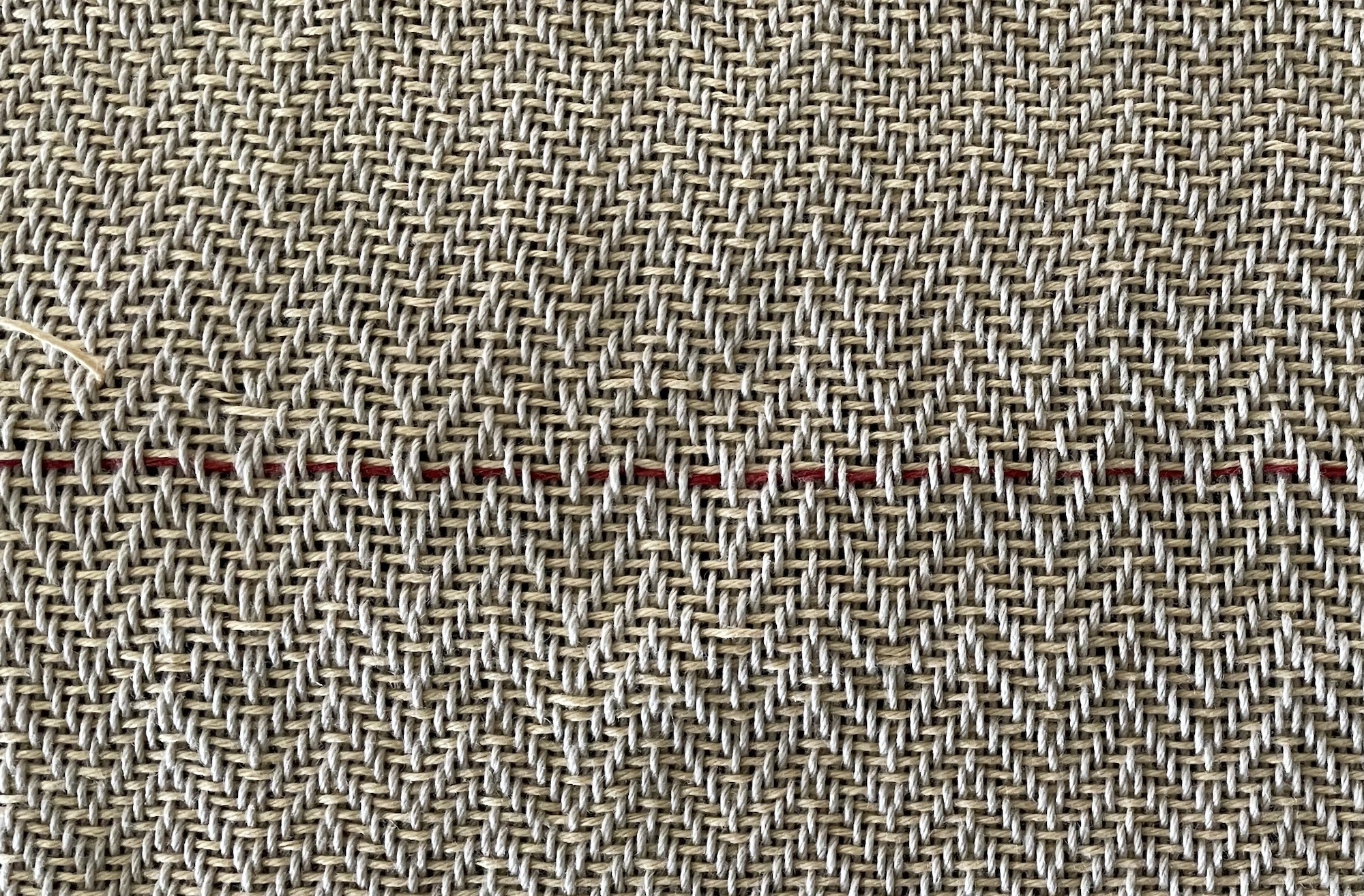

Following is a photo showing the last sample weaving, before washing, with the loops where the tangled up knots in the warp yarn caused big floats. There were other rows with mistakes also caused by the warp yarn knots, but they were not so bad. I decided to try to fix the one really bad row by weaving in a new piece of yarn by hand. In order to see the pattern better, I wove a piece of red thread through a different corresponding row of the pattern. The photos below show the bad row with the temporary red yarn on the left, and to the right, the same towel after I fixed the bad row.

Following is the last small sample towel with the bad row fixed and temporary red yarn removed, after washing. There are mistakes but it is a lot better.

The last sample towel was woven with the same treadling pattern as the yellow zig zag towel, but using yellow 8/4 cotton for the weft yarn, instead of the Gist Duet cotton/linen blend. The 8/4 cotton is a bit thicker.

Lastly is a photo of the three towels from this project next to each other, not including the smaller sample towel with the mistakes.

I am very pleased with how these towels come out. They look and feel nice, and I learned a lot in the process of weaving them. I am already on to another floor loom project I am very excited about that will be featured in a future post.

That’s a great idea to tie on to left over warp. I use a rigid heddle loom so it’s pretty quick to warp. The towels all look great and I think I prefer these to the striped warp ones.

LikeLike

I really like the new set of towels too. The rigid heddle does not have as much waste, so not as much of an issue.

LikeLike

Wow they look fantastic – it’s so surprising the amount of difference yarn type can make! I save all my loom waste (including the little bits cut off) and when I have enough I will either use it as embellishment in art yarn/weaving, or for some of my handspun wool yarns I’ve seen a few people have been carding it back into fibre again ready to spin from, which seems a good way of minimising waste. 🙂

LikeLike

I have been using some loom waste for tying warp chains. Carding it into more yarn is a great idea! Or maybe it could be plied with something else.

LikeLike

Such pretty patterns!

LikeLiked by 1 person

Thank you! Thanks for reading and enjoy your weekend.

LikeLike

These are beautiful. It is amazing how a the same pattern can look so different based on color!

LikeLike

Thank you! Yes if I had not made them myself, I would never guess they were the same pattern.

LikeLike

It is interesting when just a little change can make such a noticeable difference. The towels are beautiful!

LikeLike

Thank you! Hope you have a great day.

LikeLike

These towels are absolutely beautiful! I admire your talent and skill. I looked closely at the towels which had the pattern but looked different. I could see where it was the same pattern, but I would have never guessed it. I look forward to reading about your next project!

LikeLike

Thank you! I think the “skill” is more a matter of spending the time with it, and learning step by step. The first weaving I did was much simpler. You could do it too!

LikeLike