Like most knitters, I have many random skeins of yarn that I love, but don’t know what to do with. Some I spun myself, some I bought while on vacation, some I bought on sale, others I thought I was going to use but never made that project. They look beautiful sitting in baskets. They fill up plastic tubs. I try to think of ways to use the yarn that are worthy of their quality and beauty.

I looked through my stash in December while planning for our Arizona trip this winter. I found two skeins of yarn that worked well together for a woven scarf on my Rigid Heddle Loom. For the warp I had some Berroco Ultra Alpaca 50% Alpaca / 50% Wool leftover from a sweater, very smooth and squishy. For the weft I had a skein of Cascade Yarns Melilla 45% Silk / 35% Wool / 20% Nylon. It has a more inconsistent texture with nubs.

I wove a small sample with eight ends per inch to get an idea what they would look like together. The Melilla yarn for the weft has multiple colors that do not show up on the photo of the sample. I happened to get a section of the weft yarn that was close to the same color as the warp yarn. The woven sample was soft and I love the colors separately and together.

This is the weaving project I mentioned in my last post that involved wasting an hour and a half of time. I wanted to get this scarf warped on my rigid heddle loom, and figured it would go quickly. I took my loom and supplies over to a room in the community building at the RV Resort, where there was enough space for direct warping. After getting about 2/3 of the warp yarn on the loom the ball of yarn ran out, so I looked in my bag to get the other ball. I was swearing in my head when I saw that the other ball of yarn was not a ball of yarn. It was warp yarn that I had already measured out on my warping board at home, so that I could warp the project indirectly in the RV, without reserving a community room at the Resort. AAAHHHH. This meant that I had to remove the yarn that I had just warped on to the loom and start over.

The warp yarn was one long thread going in and out of the reed on the loom. I could have cut it off easily, but that would have ruined the yarn. Instead I pulled it out one slot at a time which took longer than it took to get it on there. I should have taken a photo of this laborious process, but I was not sure I wanted to admit I had been so dumb. After finishing that and being really disgusted with myself, I packed up all my stuff and went back to the RV. I was back to square one. It was already close to dinner time, so best to save this project for another day when I could start fresh. It was a waste of that time, but nothing else was lost.

Following is a photo of the bundle of warp yarn (“warp chain”) that I had measured at home, ready to go on the loom.

I may have warped my rigid heddle loom indirectly once before, but I wanted to review the process before starting to avoid any more dumb mistakes. As with everything, there are many sources of instruction online with many variations of steps to warp directly and indirectly. I re-watched the section from the School of Sweet Georgia class on Rigid Heddle Weaving Basics that was specifically about indirect warping.

The School of Sweet Georgia instructions suggested using lease sticks to keep the yarn ends in order, the same as when using a floor loom. That is not the only way to do it, but I decided to try their method. It was also suggested to put the yarn ends loops around the back bar instead of tying the ends on, which is essentially how it would be if I had threaded it directly. The rest of the process was similar to direct warping.

Following is a photo of the front of the loom with the yarn ends going through some makeshift lease sticks and then through the slots of the reed.

The next photo is the back of the loom, showing the loops of yarn from my warp bundle wrapped around the back bar.

The School of Sweet Georgia method recommends holding the length of warp yarn across the loom from the front to the back, creating even tension as you wind the yarn on.

After winding the warp yarn on to the back, moving one yarn end from each slot to the adjacent hole, and tying the ends on to the front apron bar, I was ready to weave. The beginning of my weft yarn was a pretty dark violet color, very different from what my small sample looks like.

I did not measure the weaving as I went, so I didn’t know how long it was when I got to the end of the warp. When I got to the end of the weft yarn on the shuttle there were a few more inches of warp available. I wanted to make sure the scarf was not too short.

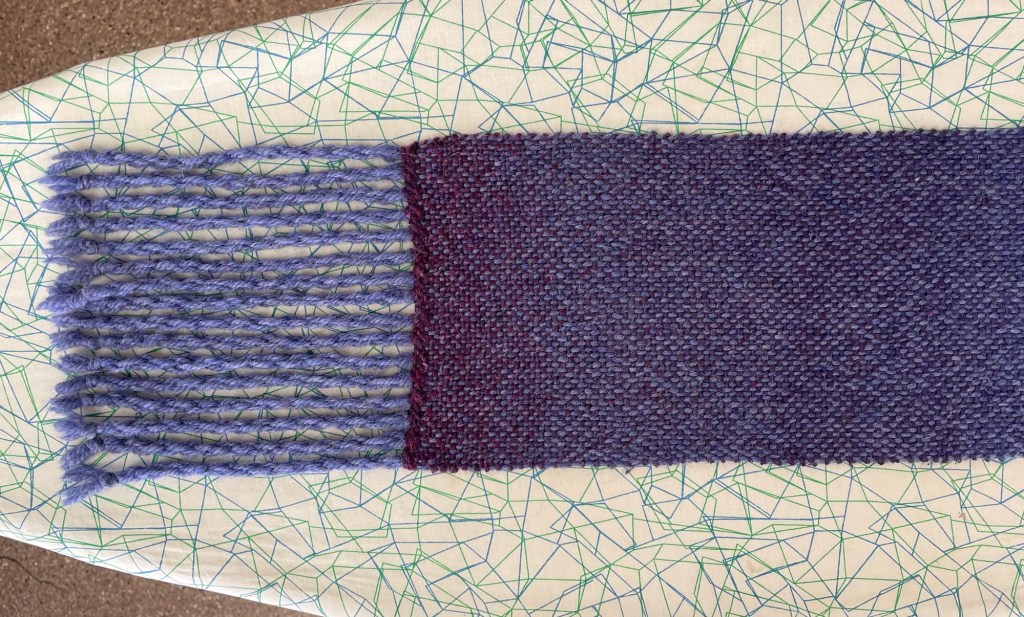

The weft yarn was variegated with different colors of blue and purple. The result was different than I expected, more Ombre than stripes. For some reason I don’t remember, I had unwound a few yards of blue at the beginning of the skein of weft yarn and set it aside. The weft yarn was purple when I got to the end of what was on the shuttle. After the purple, in order to made sure the scarf was long enough, I added the blue that I had separated off at the beginning. I worked the hem stitch so I could remove the weaving from the loom and see how long it was. Following are two photos of the weaving at the end of the loom with the extra blue yarn added after the purple.

The scarf turned out to be very long, and the abrupt transition from purple to blue did not look right, compared to the more gradual changes of color in the rest of the scarf. After seeing it off the loom, it was clear the scarf would have been plenty long and look better without the extra couple of inches of blue. I decided to remove the extra blue rows.

I worked some hem stitch at the end of the purple, and then removed the blue that did not look right. The next two photos are the entire scarf with the hem stitch added after the purple, but before I removed all of the blue.

Following is a photo after the extra blue had all been removed, and I had trimmed the warp yarn evenly for fringe.

Leaving the loose warp yarn at the ends was an option, but instead I started working twisted fringe by hand.

After gently soaking the scarf in warm water with a bit of dish soap and then rinsing, I squeezed out the extra water with a towel and laid it flat to try on the picnic table outside our RV. It was a warm day, so the scarf dried fast in the very dry Arizona conditions. Not including the fringe, the scarf is 98″ long (2.7 yards) and 6 1/2″ wide.

The next day I went over to the laundromat at the RV park and used the ironing board and iron to gently steam and press the scarf, using a linen kitchen towel for a pressing cloth.

The scarf is long enough to wrap around my neck twice. Ombre is not my favorite, but when wound and bunched up, you just notice the pretty colors.

Our time in Arizona is over for this year. The weather has been inconsistent with more rain than usual. One day last week we wore shorts and tee shirts while bike riding. The next day a sweatshirt with the new scarf was comfortable.

After being here for three months, I am ready to go home. I am even a little disappointed that we missed the winter storm that happened last week in Minnesota. As long as I do not have to go anywhere, I love working on a project in the house while watching a storm outside.

Last winter there was a lot of snow in Minnesota. When we got home in April the side of the driveway where we park the RV was piled high with a big snowbank. This year there was hardly any snow until now. The report from back home is that we got almost 10″ of snow from the recent storm, but likely it will melt by the time we get there. I would not be surprised or disappointed if there is another late season snowstorm in April, giving me an opportunity to sit inside knitting and watching the weather outside.

I love the colors in the scarf! And safe travels home!

LikeLiked by 1 person

Thank you! Smooth sailing through New Mexico today. Hope you have a good day.

LikeLiked by 1 person

The scarf is beautiful. And as always, your attention to detail is impressive. I like cozy inside days, too – just not too many of them! Safe travels home!

LikeLike

The scarf is beautiful! Safe travels home!

LikeLike

Thank you. We are back home now and it is good to be here, except that there is so much to do, like taxes. ugg.

LikeLike

The scarf is definitely a work of art.

LikeLiked by 1 person

Thank you! I have really been enjoying learning to weave.

LikeLike

Are you certain Ridgid Heddle isn’t actually a Norwegian name? like Ingrid.

The lady who ran Lake Alice Grocery when I was little was named Inga, and the very old couple who lived in our basement were named the Ladwigs.

” … It was a dark and stormy night. Inga Ladwig and Ridgid Heddle sat in their rocking chairs in front of the fireplace, drinking their tea and listening to the howling wind. .It reminded them of the old days, back in Norway…”

LikeLiked by 1 person

haha My mom wrote about Mrs Ladwig in her memoir. Rigid Heddle is a type of loom. Here is a link to an article with a photo and explanation. https://littlelooms.com/rigid-heddle-loom-resources/

LikeLike